An Overview of Class 11 Physics Youngs Modulus Of A Wire Using Searles Apparatus Experiment

With time, the perpetual need for the construction of more buildings, dams and bridges is increasing. For these industrial architects to become strong and durable, it is essential to have good knowledge of the modulus of elasticity of the material used for construction, i.e. the Young’s modulus, which we will study here.

Young’s modulus (Y) is defined as the ratio of tensile or compressive stress \[\sigma \] to the longitudinal strain \[\varepsilon \]:

\[Y = \dfrac{\sigma }{\varepsilon }\]

In this experiment, we are going to determine Young’s modulus Y of the material of a given wire using Searle’s apparatus, by determining the change in length of the wire under a constant weight using a screw gauge.

Table of Contents

Aim

Theory

Procedure

Observations

Result

Aim

To determine Young’s modulus of the material of a given wire by Searle’s apparatus.

Apparatus required

Searle apparatus

Meter scale

Small weights

Given wire

Screw gauge

Spirit level

Theory

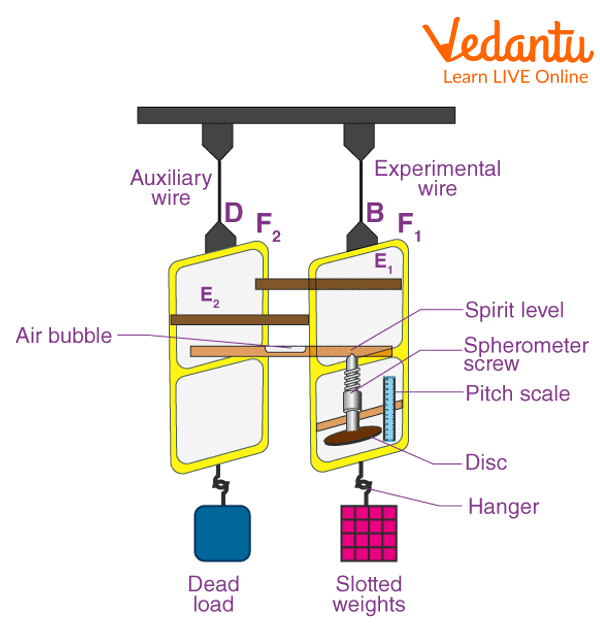

The arrangement consists of two frames that are allowed to move vertically relative to each other, joined by a spirit level. One of the frames holds a reference wire and the other one the experimental wire, which is connected to a screw gauge. Both the frames contain hooks for hanging weights to taut. Due to the additional weights, the experimental wire suffers a small length elongation, which disturbs the spirit level bubble. The screw gauge is used to adjust the bubble again at its middle position and hence gives the reading of the elongation.

The apparatus works on the principle of Hooke’s law. The Young’s modulus Y of the wire is given by:

\[Y = \dfrac{{MgL}}{{\pi {r^2}\Delta L}}\]

where M = Mass of the hanged weights

L = Original length of the wire

r = Radius of the wire

\[\Delta L\]= Extension in length of wire

g = Acceleration due to gravity

Procedure

Suspend small equal weights from both the wires to make them perfectly taut. Measure the length of each wire using a meter scale.

Determine the least count and zero error of the screw gauge. Determine the thickness of the given wire using a screw gauge at five different points on the wire. At each point, measure the thickness along two mutually perpendicular directions along its diameter and find the mean of the two. Divide it by 2 to get the radius.

Adjust the screw gauge such that the spirit level placed on the cross bar shows perfectly horizontal balance. Note the micrometer reading.

Searle’s Apparatus

Hang a weight of 0.5 kg to the given wire. The bubble in the spirit level will move away from the equilibrium position by a little bit. Adjust the screw gauge so as to bring it back to its equilibrium position. Note the reading in the screw gauge.

Increase the weight in steps of 0.5 kg and note the screw gauge reading in each case after using it to restore the position of the spirit level bubble.

Tabulate about 8 observations.

Observations

Length of the wire L =

Least count (LC) of the screw gauge =

Zero error of screw gauge =

Observation Table – For the radius of wire

MSR = Main scale reading of screw gauge

CSD = Circular scale division coinciding of screw gauge

Mean diameter after correcting zero error =

Mean radius =

Observation Table – For the Extension of Wire

Observation Table – Mean Extension in Wire Per 2 kg Load

Therefore, \[mean\;\Delta L = \dfrac{{(e - a) + (f - b) + (g - c) + (h - d)}}{4}\;cm\; = \;............\;cm\] for 2 kg

Result

Young’s modulus of the material of wire,

\[Y = \dfrac{{MgL}}{{\pi {r^2}\Delta L}} = ...........\;N{m^{ - 2}}\]

Precautions

Both wires should be taut and uniform at all points.

Measure the thickness of wires very carefully at both orthogonal positions on the same point.

Determine the zero and backlash errors of the screw gauge very carefully.

Lab Manual Questions

1. State elastic limit of a material and Hooke’s law.

Ans: The maximum applied stress allowed on a material up to the limit so as not to cause permanent deformation in it is known as the elastic limit of that material. Within this limit, the strain developed inside the material is directly proportional to the stress applied on it. This law is known as Hooke’s law.

2. Explain Young’s modulus of a material.

Ans: Young’s modulus of a material is defined as the ratio of tensile or compressive stress applied to a material to the longitudinal strain produced in that material. Its SI unit is \[N{m^{ - 2}}\].

3. On what factors does the Young’s modulus of a material depend?

Ans: Young’s modulus of a material is given by the formula

\[Y = \dfrac{{MgL}}{{\pi {r^2}\Delta L}}\]

It depends on the length L of the material, weight Mg used for deformation, its cross-sectional area \[\pi {r^2}\] and the amount of length deformation \[\Delta L\]. The value of Young’s modulus is constant for a given material but depends on external parameters such as temperature and pressure.

4. What is the rigidity modulus of a material?

Ans: Modulus of rigidity is defined as the ratio of shearing stress applied on a material to the shearing strain produced in that material. It is also known as shear modulus.

Viva Questions

1. Why does an elongation in a metallic rod hinged at one end in this experiment?

Ans: When the load is applied on the wire, the wire stretches by a small amount due to it. This strains the wire and hence the wire elongates.

2. In Young’s modulus experiment, why do we use two wires?

Ans: In Young’s modulus experiment, we use one reference wire and an experimental wire. The reference wire measures the small but finite elongation in the experimental wire due to applied load using a screw gauge.

3. Is it possible to determine the rigidity modulus of gases?

Ans: No, it is not simply possible to determine the rigidity modulus of gases because one cannot apply shearing stress on them due to large inter-particle separation and cannot measure their shearing strain.

4. In the above experiment, how do stress and strain get produced in the material?

Ans: In the above experiment, the stress is applied to the experimental wire by virtue of slotted weights, and the strain is produced in it in response due to stress applied in the form of longitudinal elongation of the wire.

5. What is Young’s modulus of elasticity?

Ans: Young’s modulus of elasticity is defined as the ratio of tensile stress to the longitudinal strain of material.

6. Give Young’s modulus formula.

Ans: The Young’s modulus Y of a material is given by:

\[Y = \dfrac{{MgL}}{{\pi {r^2}\Delta L}}\]

where F = Force applied on the material

A = Cross sectional area of the material

\[\Delta L\]= Length extension in the material

L = Given length of the material

7. If an elastic material with Young’s modulus Y is subjected to stretching stress S, obtain the expression for elastic energy stored per unit volume in the material.

Ans: Energy stored per unit volume = \[\dfrac{1}{2} \times Stress \times Strain\]

Since Young’s modulus \[Y = \dfrac{{Stress}}{{Strain}} = \dfrac{S}{{Strain}}\;\;\;\;\; \to \;\;\;\;\;Strain = \dfrac{S}{Y}\]

Therefore, energy stored per unit volume = \[\dfrac{1}{2} \times S \times \dfrac{S}{Y} = \dfrac{{{S^2}}}{{2Y}}\]

8. Define elastic deformation.

Ans: The deformation caused on an elastic body due to external deforming force before the body regains its initial shape and size is known as elastic deformation.

9. What is the shear modulus?

Ans: The ratio of shearing stress to the corresponding shearing strain of a material is known as the shear modulus of that material.

10. Give three useful examples of elasticity in Physics.

Ans: Useful examples of elasticity in physics include rubber bands, springs and trampoline.

Practical Questions

1. What is the modulus of rigidity of ideal liquids?

Zero

Unity

100

Infinite

Ans: (A) Zero

Since modulus of rigidity is a measure of rigidity of the body and ideal liquids are incompressible, non-viscous and have infinite shear strain, therefore the modulus of rigidity of ideal liquids is zero.

2. Choose the incorrect statement among the following:

Modulus of elasticity is a direct measure of the elasticity of the material

Elasticity of a material is inversely proportional to temperature

Modulus of rigidity of a material is directly proportional to temperature

For ideal fluids, bulk modulus is infinite

Ans: (C)

Modulus of rigidity of a material is independent of temperature.

3. Hooke’s law specifies:

Stress

Strain

Modulus of elasticity

Elastic limit

Ans: (C) Hooke’s law specifies the modulus of elasticity as the ratio of stress to strain within the elastic limit.

4. On which factor does the breaking stress of a wire depend?

Material of wire

Length of wire

Thickness of wire

Shape of cross-section of wire

Ans: (A) The breaking stress of a wire depends upon the material of the wire.

5. The stress at which an elastic material transforms into a plastic material is known as:

Normal stress

Ultimate stress

Thermal stress

Yield strength

Ans: (D) The stress at which an elastic material transforms into a plastic material is known as yield strength.

6. How do the elastic properties of gold change when it is electroplated with another metal?

Decrease

Vanish

Increase

Remain unaffected

Ans: (C) When gold is being electroplated with another metal, its elastic properties increase due to an increase in impurity concentration.

7. How does hammering affect the elasticity of materials?

Has no effect

Elasticity increases

Elasticity decreases

Material loses its elasticity

Ans: (B) Hammering breaks down the material into smaller units that resist the deformation more effectively. Hence, elasticity increases.

8. Why does a bridge collapse when it experiences a heavy load?

Due to weak structure

Due to increase in stress

Due to faulty materials for construction

Due to friction

Ans: (A) Due to increase in stress (force per unit area)

9. What is the effect of annealing on elasticity?

Elasticity decreases

Elasticity remains same

Elasticity increases

Elasticity increases in some regions and decreases in others

Ans: (A) Annealing results in forming larger material crystals which resist deformation less effectively. Hence, elasticity decreases.

10. What should be done to prevent the breaking of rope under a large force?

Length should be increased

Small force should be applied

Rope’s cross sectional area should be increased

Rope made of a different material should be used

Ans: (C) Upon increasing the cross sectional area of the rope, the stress experienced by it decreases due to inverse proportionality.

Conclusion

From this experiment, we can conclude that elasticity plays a crucial role in physics and engineering. Good knowledge of the elasticity of various materials plays a very important role in the construction of houses, buildings, dams and much more. It also plays a significant role in our daily lives in the form of rubber bands, trampolines, springs etc.

We hope that the reader has got a good insight into the topic through this experiment and is encouraged to explore the relevant topics in Physics.

FAQs on Class 11 Physics Youngs Modulus Of A Wire Using Searles Apparatus Experiment

1. What is the main objective of performing the Young's modulus experiment with Searle's apparatus as per the CBSE Class 11 syllabus?

The primary objective of this experiment is to determine the Young's Modulus of Elasticity (Y) for the material of a given wire. This is achieved by measuring the wire's elongation (extension) under a known tensile stress, which is applied using slotted weights. The experiment is a practical application of Hooke's Law.

2. For a 2-mark question in the exam, state Hooke's Law and define the 'elastic limit'.

Hooke's Law states that within the elastic limit, the stress applied to a body is directly proportional to the strain produced.

The elastic limit is the maximum stress a material can withstand without undergoing permanent deformation. If the stress exceeds this limit, the wire will not return to its original length after the load is removed. This is a crucial condition for the validity of this experiment.

3. What is the formula used to calculate Young's Modulus in this experiment? Define each term.

The formula to calculate Young's Modulus (Y) is:

Y = (MgL) / (πr²ΔL)

Where:

- M is the mass of the load applied to stretch the wire.

- g is the acceleration due to gravity.

- L is the original length of the experimental wire.

- r is the radius of the wire's cross-section.

- ΔL is the extension or elongation of the wire under the load M.

4. Why is it essential to use two identical wires—a reference wire and an experimental wire—in Searle's apparatus?

Using two wires is a critical design feature for accuracy. The second wire, or reference wire, helps compensate for two major sources of error:

- Thermal Expansion: Any change in room temperature will affect the length of both wires equally. Since we measure the relative displacement, the effect of temperature change is cancelled out.

- Support Yielding: The yielding or sagging of the rigid support from which the wires are hung is also compensated for, as both wires would be affected equally.

5. What are the key observations a student needs to record to find the value of Young's Modulus for the 2025-26 board practicals?

To accurately determine Young's Modulus, a student must meticulously record the following observations:

- The original length (L) of the experimental wire, measured with a metre scale.

- The diameter (and thus radius, r) of the wire, measured at multiple points using a screw gauge.

- A series of readings for the elongation (ΔL) corresponding to incremental increases in the load (M). This involves noting the micrometer reading for both increasing and decreasing loads to check for backlash error.

6. On which factors does the Young's Modulus of a material truly depend? Does changing the wire's length or thickness change its Young's Modulus?

This is a common point of confusion. Young's Modulus (Y) is an intrinsic property of a material, meaning it depends on the nature of the material itself and its internal structure. It is primarily affected by:

- Temperature: Generally, Y decreases as temperature increases.

- Impurities: The presence of impurities can alter the elastic properties.

7. Why is it a mandatory precaution to measure the wire's diameter at several different points and along mutually perpendicular directions?

This precaution is vital for minimising experimental error. The reasons are:

- Non-uniformity: The wire may not have a perfectly uniform circular cross-section throughout its length. Measuring at multiple points and averaging the result gives a more accurate value for the mean radius.

- Oval Shape: Measuring in mutually perpendicular directions at each point helps to account for any ovality (non-circularity) in the wire's cross-section.

8. What are some of the most important precautions to take while performing the Searle's apparatus experiment to get an accurate result?

For reliable results in the Class 11 Physics practical, a student should:

- Ensure both wires are free from kinks or bends.

- Start with a small initial load (dead weight) on both wires to keep them taut.

- Tap the apparatus gently before taking each reading to overcome friction.

- Read the micrometer screw gauge carefully, avoiding backlash error by always moving it in the same direction when taking a reading.

- Wait for a minute after adding a new weight to allow the wire to fully extend.

9. In the formula Y = MgL / (πr²ΔL), which measurement is the most likely source of significant error and why?

The measurement of the radius (r) of the wire is the most critical source of error. This is because the radius term is squared (r²) in the denominator. According to the principles of error propagation, the percentage error in 'r' gets multiplied by two in the final calculation of 'Y'. Therefore, even a small mistake in measuring the diameter with the screw gauge can lead to a large error in the determined value of Young's Modulus.

10. How do mechanical processes like hammering and thermal processes like annealing affect the elasticity of a wire?

These processes have opposite effects on elasticity:

- Hammering (or rolling): This is a cold-working process that breaks the material into smaller crystal grains. This increases resistance to deformation and therefore increases the elasticity of the material.

- Annealing: This involves heating the material to a high temperature and then cooling it slowly. This process forms larger, more uniform crystal grains, which reduces internal stresses and makes the material softer and more ductile. As a result, annealing decreases the elasticity.