Why Is Damping Torque Important in Physics and Engineering?

For an instrument to indicate the readings, it needs to have three important systems called a deflection system, controlling system and damping system, which respectively, provide three torques called as deflecting torque, controlling torque and damping torque. These three torques are necessary for indicating instruments.

The use of damping torque is to remove oscillation and vibration and bring the pointer at rest in a quick manner in indicating instruments. In other words, we can say that damping torque is required to stop the vibration of the pointer to read accurate value on the scale.

Importance of Damping Torque

Damping torque is the torque which is required to reduce the number of oscillations. If the damping torque is absent, it will require several time-consuming processes in order to take each and every reading. Here lies the importance of damping torque in all indicating type analogue instruments.

Main Function of Damping Torque

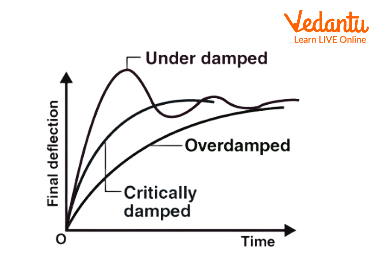

The main function of damping torque is to damp or reduce the number of oscillations that the pointer or the deflecting system undergoes. As the number of oscillations is reduced, it comes to steady or equilibrium state faster and the reading can be taken quickly. We can represent three conditions of this damping torque by a graph shown here.

Dynamic Response of a Measuring Instrument

The above graph shows the conditions of damping torque. The behaviour of the moving system can be decided from the degree of damping.

From the above graph, we can say that the pointer will become slow, if the instrument is over-damped.

Critical damping is when the pointer returns to its equilibrium position in a small amount of time without doing any oscillation. Instruments such as speedometers come under this category.

When the response is oscillatory, we can say that the instrument is under-damped.

Requirement of Damping Torque

To bring the moving system to a stop, damping torque is always required in the measuring instrument and it exhibits stable reflection in an acceptable amount of time. In other words, we can say that to bring the moving system to rest to indicate steady reflection in a very short amount of time, damping torque is required.

Different Types of Methods to Produce Damping Torque

The damping torque can be produced by the following three methods:

Air Friction Damping

Fluid Friction Damping

Eddy Current Damping

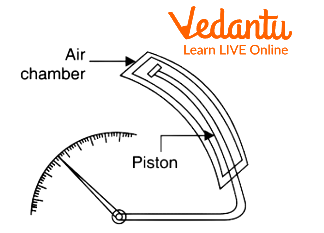

In air friction damping torque, a light aluminium vane is attached to the moving system, which moves in an air chamber. The air pressure inside the chamber restricts the movement of the vane and provides required damping torque.

Air Friction Damping

Air friction damping method is very simple and low maintenance. It does not require a permanent magnet and hence there would be no problem of distortion.

Generally, air friction damping is used where low value of the magnetic field is required.

Air friction damping is generally used in moving iron and electrodynamometer type instruments. Moving iron type instruments can work on both AC and DC.

Air friction damping is used in thermal instruments as well.

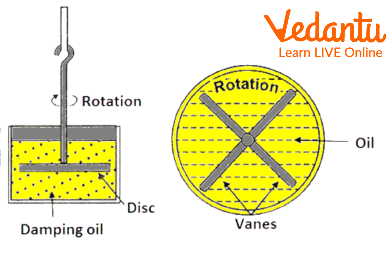

In fluid friction damping, a light aluminium vane is attached to the moving system, which is placed inside the fluid container so that friction offered by the fluid can oppose the motion of the pointer. The friction offered by liquid is more compared to the friction offered by air. So, fluid friction can provide more damping force.

Fluid friction damping is generally used for laboratory type electrostatic type instruments.

It is used in wall mounted type instruments as well.

Fluid Friction Damping

Due to leakage of fluid, it is not easy to keep the instrument clean every time. Moreover, it requires more maintenance and its cost is also very high. Fluid viscosity should not change with temperature. It is not suitable for repeated operations. These are the major drawbacks of fluid friction damping. Apart from that, fluid should not evaporate quickly. Also, fluid should not have any corrosive action upon the metal of the instrument. So, these are the drawbacks of the fluid friction damping method.

Eddy Current Damping

According to Faraday’s law, whenever the change takes place in the magnetic flux which is linked with the circuit, an emf current is induced in the circuit. This current can produce an electromagnetic torque due to the magnetic field. This will oppose the direction of motion. Hence, electromagnetic torque provides the necessary damping force.

Eddy current damping is used where a high value of the magnetic field is required. For instance, eddy current damping is generally used in Permanent Magnetic Moving Coil which is known as PMMC and it is an instrument which is used to measure current or voltage. The advantage of PMMC is that it has less power consumption and high accuracy.

Eddy current damping is also used in induction type instruments.

Solved Examples

1. A PMMC ammeter has a rectangular coil $2cm \times 3cm$ with 100 turns and is placed in a uniform magnetic field of density $0.1\dfrac{{Wb}}{{{m^2}}}$ The spring constant is $2.0 \times {10^{ - 7}}$ Nm per degree. Find the deflection of the coil, when it carries a current of 10mA ac.

Ans: Given: $N = 100turns$

spring constant $k = 2.0 \times {10^{ - 7}}$ Nm per degree

Magnetic field $B = 0.1\dfrac{{Wb}}{{{m^2}}}$

The deflection of the coil will be zero in case of alternating current. This means that there will be no deflection, since average torque is zero in case of an ac.

2. The torque of an ammeter varies as the square of the current through it. If a current of 10A produces a deflection of $90^\circ $, what deflection will occur for a current of 5A when the instrument is spring controlled?

Ans: Given:

$\begin{array}{l}{I_1} = 10A\\{\theta _1} = 90^\circ \\{I_2} = 5A\end{array}$

In spring control, deflection is proportional to $\theta $

So, we can say that current is proportional to $\theta $

$\begin{array}{l}\therefore \dfrac{{{I_1}}}{{{I_2}}} = \dfrac{{{\theta _1}}}{{{\theta _2}}}\\ \Rightarrow \dfrac{{10}}{5} = \dfrac{{90^\circ }}{{{\theta _2}}}\end{array}$

$\therefore {\theta _2} = \dfrac{{5 \times 90^\circ }}{{10}} = 45^\circ$

Interesting Facts

For the electro dynamometer type instruments, we can not use eddy current damping because the operating field is very weak.

Damping is necessary for an electromechanical measuring instrument.

Moving coil galvanometer is not suitable to measure alternating current.

Conclusion

The damping torque in indicating type instrument can be provided by air friction damping, fluid friction damping and eddy current damping method. Eddy current damping is the most efficient method as compared to the other methods. This was the complete discussion on damping torque and its importance. We hope you have found it interesting and informative enough. Try to solve the above questions on your own and visit our website for further reading on similar topics.

FAQs on Damping Torque in Physics: Definition, Formula & Applications

1. What is damping torque and why is it essential for measuring instruments?

Damping torque is a type of opposing torque in measuring instruments that acts only when the pointer is in motion. Its primary function is to dampen the oscillations of the pointer, allowing it to settle at its final position quickly and without overshooting. It is essential because, without it, the pointer would oscillate around the correct reading for a long time, making it difficult and time-consuming to take an accurate measurement.

2. What are the three essential torques required for an indicating instrument to function correctly?

For an indicating instrument to provide an accurate reading, three distinct torques must work together:

- Deflecting Torque (Td): This is the primary torque that causes the moving system and the pointer to move from its zero position. It is generated by the quantity being measured (e.g., current or voltage).

- Controlling Torque (Tc): This torque opposes the deflecting torque and increases with the pointer's deflection. It ensures the pointer stops at the correct value where Tc = Td.

- Damping Torque (TD): This torque opposes the motion of the pointer and acts to quickly eliminate oscillations, ensuring the pointer comes to a steady state.

3. How does damping torque differ from controlling torque in a measuring instrument?

The key difference lies in their function and when they act. Controlling torque depends on the pointer's position (deflection) and determines the final steady reading by balancing the deflecting torque. In contrast, damping torque depends on the pointer's speed and only acts when the system is moving. Its sole purpose is to prevent oscillations and bring the pointer to rest efficiently, it does not affect the final accuracy of the reading.

4. What are the main methods for producing damping torque in instruments?

There are three primary methods used to generate damping torque in indicating instruments:

- Air Friction Damping: Uses the resistance of air acting on a lightweight aluminium vane attached to the moving system.

- Fluid Friction Damping: Similar to air friction but uses a vane moving in a high-viscosity oil, which provides a much stronger damping force.

- Eddy Current Damping: Utilises electromagnetic principles where eddy currents induced in a moving conductor within a magnetic field create an opposing torque.

5. Compare the working principles of air friction damping and eddy current damping.

Air friction damping is a mechanical method that relies on the physical resistance of air pushing against a moving vane. It's simple and cheap but provides relatively weak damping. In contrast, eddy current damping is an electromagnetic method. It works on the principle that when a conductor moves through a magnetic field, it induces eddy currents. These currents create their own magnetic field that opposes the motion, resulting in a highly effective and smooth damping force without any physical contact or friction.

6. What is eddy current damping and in which type of instrument is it most commonly used?

Eddy current damping is a highly efficient damping method based on Faraday's law of electromagnetic induction. When a non-magnetic conducting material (like an aluminium disc or former) moves in a strong magnetic field, eddy currents are induced in it. These currents produce a torque that opposes the motion. This method is most commonly used in instruments with a strong permanent magnet, such as the Permanent Magnet Moving Coil (PMMC) instrument, due to its high accuracy and effectiveness.

7. Why is eddy current damping often preferred over air or fluid friction methods?

Eddy current damping is often preferred because it is the most efficient method. Unlike fluid friction damping, it has no risk of liquid leakage, does not require maintenance, and is not affected by temperature changes that can alter fluid viscosity. Compared to air friction damping, it provides a much stronger and more consistent damping force, allowing the instrument's pointer to settle much faster. This leads to more reliable and quicker instrument readings.

8. What do the terms underdamped, critically damped, and overdamped mean in the context of an instrument's pointer?

These terms describe the dynamic response of the instrument's pointer after a deflection:

- Underdamped: The pointer oscillates back and forth around the final reading before coming to rest.

- Overdamped: The pointer moves very slowly and sluggishly towards the final reading without any oscillation.

- Critically Damped: This is the ideal condition where the pointer moves to the final position in the shortest possible time without any oscillation. Most indicating instruments are designed to be critically damped for optimal performance.

9. Why can't eddy current damping be used in electrodynamometer type instruments?

Eddy current damping cannot be used in electrodynamometer type instruments because this damping method relies on a strong, permanent magnetic field to induce significant eddy currents. Electrodynamometers operate with a much weaker magnetic field generated by their own coils. This weak operating field is insufficient to produce the necessary electromagnetic torque for effective damping, so these instruments typically use air friction damping instead.