What is the condition for zero error in screw gauge?

A.)When zero of circular scale is not coinciding with datum line

B.)When zero of circular scale is coinciding with datum line

C.)There is no specific condition for zero error.

D.)None of the above

Answer

595.8k+ views

Hint: Error is basically the deviation of measured quantity from its true value. So. Zero error can be seen as a deviation of reading from calibrated zero point while working with an instrument. Basically, it is an indication of an instrument resulting in a non-zero value for some quantity when the quantity is actually zero.

Complete step-by-step answer:

A screw gauge is an instrument used to measure small lengths such as the thickness of a thin glass plate or the diameter of a wire, which are basically measured in milli-metre. It works on the principal of a screw in a nut, hence called a screw gauge.

It consists of a U-shaped metallic frame, a main scale and a circular scale fitted on a cylinder. There are calibrations done on horizontal main scale and circular scale, calibrations of which are used to find the required values of thickness.

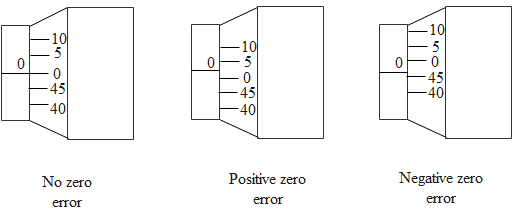

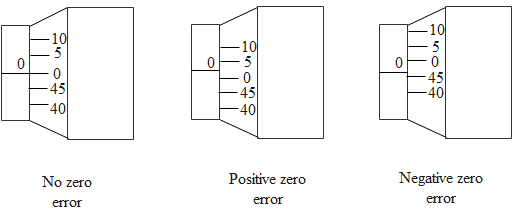

Either due to miscalibrated instrument or personal misjudgement while experimenting, the zero of circular scale may not coincide with the datum or reference line of the main scale thus causing an error in reading of the screw gauge. So, if the zero of the circular scale is above or below the zero of the main scale, then it is known as zero error.

Hence, the correct answer is .

Note: When the zero mark on the circular scale is below the reference line of the main scale, then the error is said to be a positive zero error. And when the zero mark on the circular scale is above the reference line of the main scale, then the error is said to be a negative zero error.

Complete step-by-step answer:

A screw gauge is an instrument used to measure small lengths such as the thickness of a thin glass plate or the diameter of a wire, which are basically measured in milli-metre. It works on the principal of a screw in a nut, hence called a screw gauge.

It consists of a U-shaped metallic frame, a main scale and a circular scale fitted on a cylinder. There are calibrations done on horizontal main scale and circular scale, calibrations of which are used to find the required values of thickness.

Either due to miscalibrated instrument or personal misjudgement while experimenting, the zero of circular scale may not coincide with the datum or reference line of the main scale thus causing an error in reading of the screw gauge. So, if the zero of the circular scale is above or below the zero of the main scale, then it is known as zero error.

Hence, the correct answer is .

Note: When the zero mark on the circular scale is below the reference line of the main scale, then the error is said to be a positive zero error. And when the zero mark on the circular scale is above the reference line of the main scale, then the error is said to be a negative zero error.

Recently Updated Pages

Master Class 11 Computer Science: Engaging Questions & Answers for Success

Master Class 11 Business Studies: Engaging Questions & Answers for Success

Master Class 11 Economics: Engaging Questions & Answers for Success

Master Class 11 English: Engaging Questions & Answers for Success

Master Class 11 Maths: Engaging Questions & Answers for Success

Master Class 11 Biology: Engaging Questions & Answers for Success

Trending doubts

One Metric ton is equal to kg A 10000 B 1000 C 100 class 11 physics CBSE

There are 720 permutations of the digits 1 2 3 4 5 class 11 maths CBSE

Discuss the various forms of bacteria class 11 biology CBSE

Draw a diagram of a plant cell and label at least eight class 11 biology CBSE

State the laws of reflection of light

Explain zero factorial class 11 maths CBSE