Draw a labelled diagram of floating gas holder type biogas plant and describe its working. Mention any two advantages of using animal dung for making biogas over using it as a fuel in the form of dried dung cakes.

Answer

572.1k+ views

Hint: The by-product of the biogas production process is organic (digestate), an ideal complement to chemical fertilisers and/or substitute for them. Digester fertiliser discharge can accelerate plant growth, resilience to disease while commercial fertilisers contain toxic chemicals, including food toxicity.

Complete solution:

Biogas is both a clean and renewable energy source. Non-polluting gas is generated by bio digestion; it directly decreases carbon emissions (i.e. the greenhouse effect). There is no oxidation during this process which ensures that greenhouse gases are not released to the atmosphere; therefore, the use of waste gas as an energy form is a perfect way to tackle global warming. Not unexpectedly, environmental interest is an important explanation why the use of biogas is growing. The greenhouse effect is greatly minimised by biogas plants: the methane emissions are reduced by capturing and using this toxic gas as a fuel. The production of biogas helps minimise dependence on fossil fuels including oil and coal. Another value is that the process is normal and does not require electricity for the process of generation, as opposed to other forms of renewable energy.

Overflowing landfills are not only a source of odour but are also a source of harmful liquids. As a consequence, biogas production can boost water quality, which provides yet another benefit. In comparison, anaerobic digestion disables pathogens and parasites, which ensures that the occurrence of waterborne diseases is often very successful. In areas of biogas facilities, waste disposal and management have also enhanced considerably. This in turn leads to environmental, sanitary and hygiene changes.

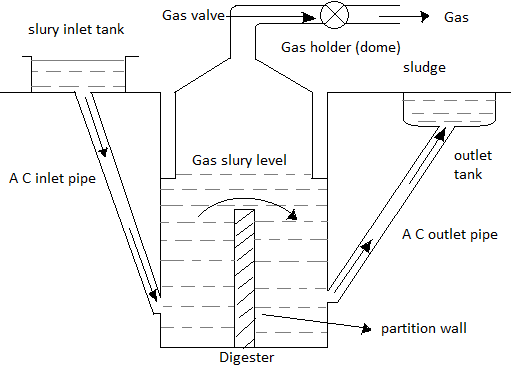

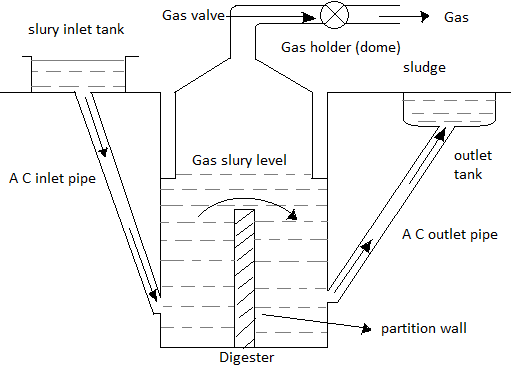

The biogas plant has a digester in the shape of a cup in which cow dung is maintained. It is fully isolated and therefore has no oxygen. In this situation anaerobic. Methanogens (methanol producing bacteria) perform its function by digestion of the cow dung and produce methanol. Carbon dioxide, as well as methane. Sulphide hydrogen is also generated. The gases are thus produced, while the rest can be used as fertiliser from the gas outlet.

Working:

The biogas plant can be used as a substratum for feeding organic input materials including residues of fruit, fats or sludge. In the biogas farm, green energy sources like maize, beets, odder grass feed all animals like cows and pigs and micro-organisms. Dung and compost are fed to the biogas plant as well. Heated to around in the fermenter. The substratum is broken down by 38-40 °C, with absence of light and oxygen, by microorganisms. Biogas with methane as the main component is the ultimate product of this fermentation process. However the biogas contains even violent hydrogen sulphide. A steel fermenter has the apparent benefit of being capable of treating hydrogen sulphide attacks and is usable for decades. In addition, the biogas plant can also be run in thermophilic temperatures up to 56°C) using a stainless steel fermenter.

If the substratum is fermented, it is transferred to the final holding tank with fermentation residues and can be collected for further usage. The residues can be used as fertilisers of high quality. The drawback is that the viscosity of biogas dung is smaller and thus penetrates the soil quicker. In comparison, the residue of fermentation also has a higher fertiliser content, and in the olfactory senses is less severe.

However it is also an alternative to dry and then used as a dry fertiliser. This biogas is deposited on the tank's top, and it is then used to produce electricity and fuel in the combined heat and power plant (CHP).

Strom is supplied to the energy grid directly. The produced heat may be used for cooking, drying wood or harvesting goods. Biogas therapy. Gas supply to domestic grid and gas tankers

Note: Biogas is a relatively cheap technology. It is simple to set up and requires a small amount of investment. Kitchen waste and animal manure can be used at home as small bio digesters. After some time, a household system pays for itself and the materials used are completely free. The manifested gas can be specifically used for cooking and electricity generation. This makes it possible to produce relatively low costs of biogas.

Complete solution:

Biogas is both a clean and renewable energy source. Non-polluting gas is generated by bio digestion; it directly decreases carbon emissions (i.e. the greenhouse effect). There is no oxidation during this process which ensures that greenhouse gases are not released to the atmosphere; therefore, the use of waste gas as an energy form is a perfect way to tackle global warming. Not unexpectedly, environmental interest is an important explanation why the use of biogas is growing. The greenhouse effect is greatly minimised by biogas plants: the methane emissions are reduced by capturing and using this toxic gas as a fuel. The production of biogas helps minimise dependence on fossil fuels including oil and coal. Another value is that the process is normal and does not require electricity for the process of generation, as opposed to other forms of renewable energy.

Overflowing landfills are not only a source of odour but are also a source of harmful liquids. As a consequence, biogas production can boost water quality, which provides yet another benefit. In comparison, anaerobic digestion disables pathogens and parasites, which ensures that the occurrence of waterborne diseases is often very successful. In areas of biogas facilities, waste disposal and management have also enhanced considerably. This in turn leads to environmental, sanitary and hygiene changes.

The biogas plant has a digester in the shape of a cup in which cow dung is maintained. It is fully isolated and therefore has no oxygen. In this situation anaerobic. Methanogens (methanol producing bacteria) perform its function by digestion of the cow dung and produce methanol. Carbon dioxide, as well as methane. Sulphide hydrogen is also generated. The gases are thus produced, while the rest can be used as fertiliser from the gas outlet.

Working:

The biogas plant can be used as a substratum for feeding organic input materials including residues of fruit, fats or sludge. In the biogas farm, green energy sources like maize, beets, odder grass feed all animals like cows and pigs and micro-organisms. Dung and compost are fed to the biogas plant as well. Heated to around in the fermenter. The substratum is broken down by 38-40 °C, with absence of light and oxygen, by microorganisms. Biogas with methane as the main component is the ultimate product of this fermentation process. However the biogas contains even violent hydrogen sulphide. A steel fermenter has the apparent benefit of being capable of treating hydrogen sulphide attacks and is usable for decades. In addition, the biogas plant can also be run in thermophilic temperatures up to 56°C) using a stainless steel fermenter.

If the substratum is fermented, it is transferred to the final holding tank with fermentation residues and can be collected for further usage. The residues can be used as fertilisers of high quality. The drawback is that the viscosity of biogas dung is smaller and thus penetrates the soil quicker. In comparison, the residue of fermentation also has a higher fertiliser content, and in the olfactory senses is less severe.

However it is also an alternative to dry and then used as a dry fertiliser. This biogas is deposited on the tank's top, and it is then used to produce electricity and fuel in the combined heat and power plant (CHP).

Strom is supplied to the energy grid directly. The produced heat may be used for cooking, drying wood or harvesting goods. Biogas therapy. Gas supply to domestic grid and gas tankers

Note: Biogas is a relatively cheap technology. It is simple to set up and requires a small amount of investment. Kitchen waste and animal manure can be used at home as small bio digesters. After some time, a household system pays for itself and the materials used are completely free. The manifested gas can be specifically used for cooking and electricity generation. This makes it possible to produce relatively low costs of biogas.

Recently Updated Pages

Master Class 10 Computer Science: Engaging Questions & Answers for Success

Master Class 10 General Knowledge: Engaging Questions & Answers for Success

Master Class 10 English: Engaging Questions & Answers for Success

Master Class 10 Social Science: Engaging Questions & Answers for Success

Master Class 10 Maths: Engaging Questions & Answers for Success

Master Class 10 Science: Engaging Questions & Answers for Success

Trending doubts

What is the median of the first 10 natural numbers class 10 maths CBSE

Which women's tennis player has 24 Grand Slam singles titles?

Who is the Brand Ambassador of Incredible India?

Why is there a time difference of about 5 hours between class 10 social science CBSE

Write a letter to the principal requesting him to grant class 10 english CBSE

A moving boat is observed from the top of a 150 m high class 10 maths CBSE