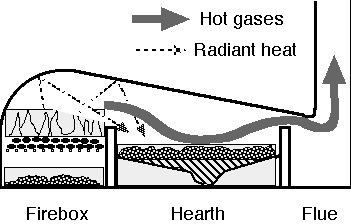

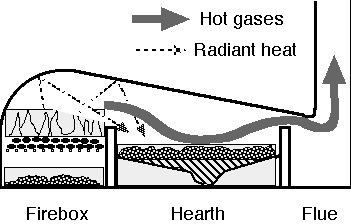

Draw a neat diagram of a Reverberatory furnace and label its parts?

Answer

573.3k+ views

Hint: Reverberatory furnace is an apparatus which we use in making nickel, copper or tin, metals like that. Usually for the process of smelting and refining or these metals from its ores.

Reverberatory smelting has recent application in giving way to such newer processes as continuous smelting and the use of electric or flash furnaces.

Complete step by step answer:

Reverberatory furnace, which is used in production of copper, nickel and tin, is a furnace used for refining or smelting in which the fuel does not come in direct contact with the ore of the materials but instead it heats it with the help of a flame which is, blown over it from some other chamber. In the production of steel, this process is termed as the open-hearth process. We pass the heat over the hearth, in which we place the ore, and then it reverberates back. The roof is curved, along with the highest point which is located over the firebox. And then it slopes downward toward a bridge made up of flues that deflect the flame so that it reverberates. The hearth is made thick and waterproof so that the heavy matte, or molten impure metal, cannot enter through and into it, and we make the walls with the material which resists chemical attack by the slag. The process is continuous in the reverberatory furnace: concentrate of ore is charged through openings which are present in the roof; slag, which rises to the top, overflows continuously at one end; and the matte is tapped at intervals from the deepest part of the ore bath for transfer to a converter, where it is further refined.

A number of technical innovations have improved the capacity of production of this furnace, although its basic construction has remained the same. Roofs were made of refractory brick instead of the ordinary brick used earlier, and this has permitted higher temperatures which in turn resulted in faster refining. Reverberatory smelting has recently been giving way to such newer processes as continuous smelting and the use of electric or flash furnaces.

Note: Reverberatory furnaces which are usually termed as air furnaces in this context, were at first also used for melting pig iron, brass, and bronze for foundry work.

For the first \[75{ }years\] of the \[20th\] century they were also, the dominant smelting furnace used in production of copper, treating either roasted calcine or raw copper sulfide concentrate

Reverberatory smelting has recent application in giving way to such newer processes as continuous smelting and the use of electric or flash furnaces.

Complete step by step answer:

Reverberatory furnace, which is used in production of copper, nickel and tin, is a furnace used for refining or smelting in which the fuel does not come in direct contact with the ore of the materials but instead it heats it with the help of a flame which is, blown over it from some other chamber. In the production of steel, this process is termed as the open-hearth process. We pass the heat over the hearth, in which we place the ore, and then it reverberates back. The roof is curved, along with the highest point which is located over the firebox. And then it slopes downward toward a bridge made up of flues that deflect the flame so that it reverberates. The hearth is made thick and waterproof so that the heavy matte, or molten impure metal, cannot enter through and into it, and we make the walls with the material which resists chemical attack by the slag. The process is continuous in the reverberatory furnace: concentrate of ore is charged through openings which are present in the roof; slag, which rises to the top, overflows continuously at one end; and the matte is tapped at intervals from the deepest part of the ore bath for transfer to a converter, where it is further refined.

A number of technical innovations have improved the capacity of production of this furnace, although its basic construction has remained the same. Roofs were made of refractory brick instead of the ordinary brick used earlier, and this has permitted higher temperatures which in turn resulted in faster refining. Reverberatory smelting has recently been giving way to such newer processes as continuous smelting and the use of electric or flash furnaces.

Note: Reverberatory furnaces which are usually termed as air furnaces in this context, were at first also used for melting pig iron, brass, and bronze for foundry work.

For the first \[75{ }years\] of the \[20th\] century they were also, the dominant smelting furnace used in production of copper, treating either roasted calcine or raw copper sulfide concentrate

Recently Updated Pages

Master Class 11 Computer Science: Engaging Questions & Answers for Success

Master Class 11 Business Studies: Engaging Questions & Answers for Success

Master Class 11 Economics: Engaging Questions & Answers for Success

Master Class 11 English: Engaging Questions & Answers for Success

Master Class 11 Maths: Engaging Questions & Answers for Success

Master Class 11 Biology: Engaging Questions & Answers for Success

Trending doubts

One Metric ton is equal to kg A 10000 B 1000 C 100 class 11 physics CBSE

There are 720 permutations of the digits 1 2 3 4 5 class 11 maths CBSE

Discuss the various forms of bacteria class 11 biology CBSE

Draw a diagram of a plant cell and label at least eight class 11 biology CBSE

State the laws of reflection of light

Explain zero factorial class 11 maths CBSE