Explain the principle and working of a biogas plant using a labelled schematic diagram.

Answer

569.7k+ views

Hint : This question can be answered using the fact that the biogas is produced by the anaerobic decomposition of the biomass or the organic matter. The biomass is usually taken to be cow dung.

Complete step by step answer

The principle of the biogas plant is that when the decomposition of the organic matter is made in the anaerobic conditions, then biogas is produced.

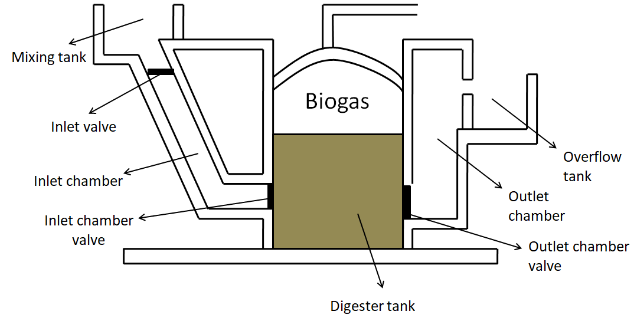

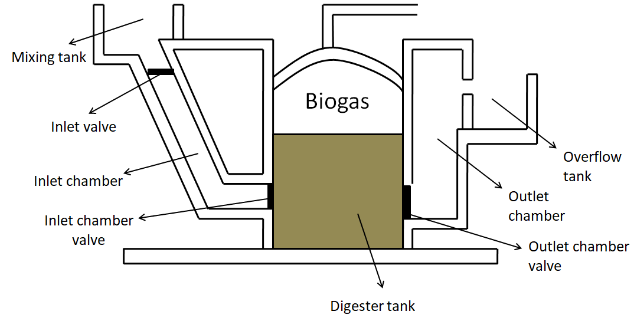

The schematic diagram of a biogas plant is shown below.

Working:

The organic matter which is used in the biogas plant is usually cow dung. It is mixed in water to form the slurry. The slurry is transferred to the mixing tank, while the inlet valve is closed. Then the inlet valve is opened so that the slurry enters the inlet chamber, while the inlet chamber valve is kept closed. Then the inlet chamber valve is opened due to which the slurry enters the digester tank, due to which it is partially filled by the slurry. The digester is kept free of oxygen. The outlet valve is kept closed and the slurry is kept in the digester tank for about two months. In this period the anaerobic bacteria inside the digester tank decomposes the slurry due to which biogas is produced which rises up and is collected through the upper outlet. The remaining slurry is collected from the overflow tank via the outlet chamber after opening the outlet chamber valve. This remaining slurry is used as manure for new plants.

Note

The biogas produced by the biogas plant described above is very useful in daily uses. It can be used to generate electricity. When it is compressed, it acts as a good replacement to the compressed natural gas (CNG). Also, it is used for cooking purposes, as it generates heat.

Complete step by step answer

The principle of the biogas plant is that when the decomposition of the organic matter is made in the anaerobic conditions, then biogas is produced.

The schematic diagram of a biogas plant is shown below.

Working:

The organic matter which is used in the biogas plant is usually cow dung. It is mixed in water to form the slurry. The slurry is transferred to the mixing tank, while the inlet valve is closed. Then the inlet valve is opened so that the slurry enters the inlet chamber, while the inlet chamber valve is kept closed. Then the inlet chamber valve is opened due to which the slurry enters the digester tank, due to which it is partially filled by the slurry. The digester is kept free of oxygen. The outlet valve is kept closed and the slurry is kept in the digester tank for about two months. In this period the anaerobic bacteria inside the digester tank decomposes the slurry due to which biogas is produced which rises up and is collected through the upper outlet. The remaining slurry is collected from the overflow tank via the outlet chamber after opening the outlet chamber valve. This remaining slurry is used as manure for new plants.

Note

The biogas produced by the biogas plant described above is very useful in daily uses. It can be used to generate electricity. When it is compressed, it acts as a good replacement to the compressed natural gas (CNG). Also, it is used for cooking purposes, as it generates heat.

Recently Updated Pages

Master Class 11 Computer Science: Engaging Questions & Answers for Success

Master Class 11 Business Studies: Engaging Questions & Answers for Success

Master Class 11 Economics: Engaging Questions & Answers for Success

Master Class 11 English: Engaging Questions & Answers for Success

Master Class 11 Maths: Engaging Questions & Answers for Success

Master Class 11 Biology: Engaging Questions & Answers for Success

Trending doubts

There are 720 permutations of the digits 1 2 3 4 5 class 11 maths CBSE

Discuss the various forms of bacteria class 11 biology CBSE

Explain zero factorial class 11 maths CBSE

What organs are located on the left side of your body class 11 biology CBSE

Draw a diagram of nephron and explain its structur class 11 biology CBSE

How do I convert ms to kmh Give an example class 11 physics CBSE