What is the purpose of ratchet in a screw-gauge?

(A) Preventing the spindle from moving further

(B) Supporting the frame of screw gauge

(C) Moving the spindle smoothly

(D) None of these

Answer

562.8k+ views

Hint : In order to solve this question we need to know about the screw-gauge that a ratchet helps to advance the screw by turning it until the object is gently held between the stud and spindle of the screw and it applies pressure by slipping at a predetermined torque.

Complete Step By Step Answer:

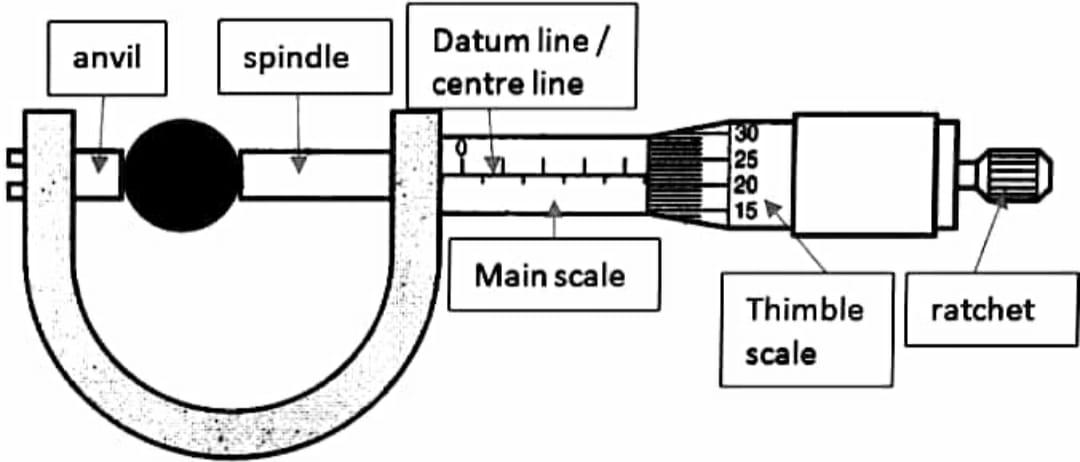

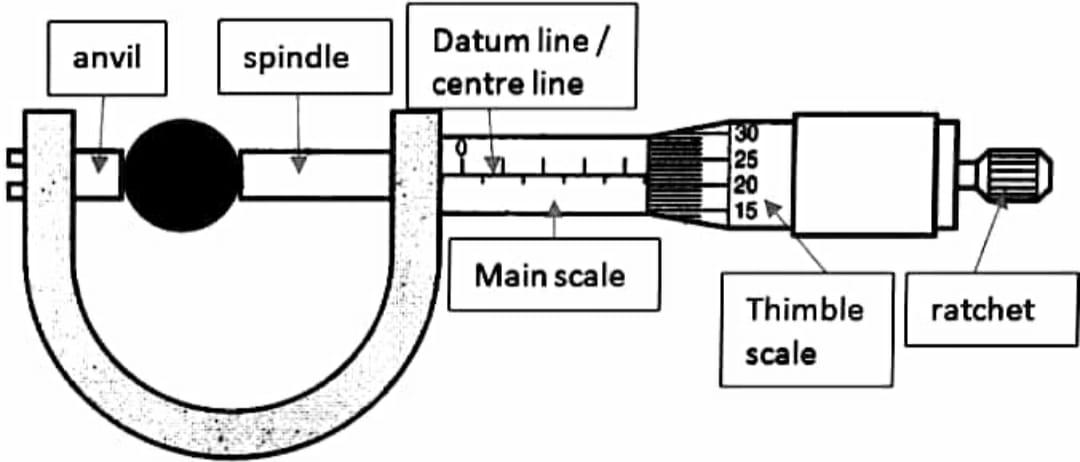

For solving this question we need to know the screw-gauge or micrometer screw-gauge is a measuring instrument used for precision measurement. A measuring device used extensively in the mechanical engineering field, micrometer screw gauge is used for measuring extremely small dimensions. A screw-gauge can even measure dimensions smaller than those measured by Vernier calipers. Belonging to the family of calipers, micrometer screw-gauges also contain two different scales.

Now we will study about its constructions and parts:

A screw gauge consists of “U” shaped metallic structure, which is attached to a hollow cylinder tube on one end. The hollow tube has a uniformly threaded nut inside it. A long stud with a plane phase is fitted into this nut. Exactly on the opposite side of this nut and on the other end of the U shaped frame, a smaller stud with a plane face is also attached. Faces of both the studs are exactly parallel to each other.

This U shaped metallic structure is known as the frame of micrometer screw gauge. The smaller stud is known as a frame of micrometer screw gauge. The smaller stud is known as the anvil and the longer one is known as spindle. The anvil is a fixed part of the device, whereas the spindle moves as and when the head is moved. The frame carries both the anvil and barrel, and is also heavier than the rest parts. The object to be measured is held between the anvil and the spindle.

The barrel or sleeve connects the frame to a cylindrical tube. . It is a non-movable part of the screw gauge and has a scale inscribed over it which is the main scale of the device. Moreover, it also carries the most important part of the micrometer- the screw.

The screw is the heart of the micrometer and is located inside the barrel. The screw converts small dimensions into measurable distance using a scale. The thimble or head is the end of the cylindrical tube and is turned to move and adjust the spindle. The thimble carries the vernier or secondary scale. There is one more part called the ratchet which is provided at the end of the tube. The ratchet is a kind of limiting device which applies a pressure by slipping at a predetermined torque and thus prevents the spindle from moving further. Some screw gauges also consist of locking devices which hold the scales at a particular position for prevent any kind of error while taking readings.

Thus the main parts of a micrometer screw gauge are:

-Frame

-Anvil

-Spindle

-Sleeve

-Thimble

-Ratchet

-Screw

Now we will study these one by one:

Frame: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Anvil: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Spindle: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Thimble: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Sleeve: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Ratchet: The hollow cylinder leads to a ratchet which is meant for fine adjustment. The U frame consists of a flat end known as stud and a screw on the other side. This screw can be moved inside the nut by fitted in the U frame by rotating the hollow cylinder called the thimble. This is called the main scale.

Screw: Micrometer screw gauge is a device incorporating a calibrated screw is widely used for precise measurement of components in the manufacturing of mechanical parts. The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used.

Hence our option A is correct.

Note:

Now we will be studying about the working principle of it:

Micrometer Screw gauge works on the simple principle of converting small distances into larger ones by measuring the rotation of the screw. This “screw” principle facilitates reading of smaller distances on a scale after amplifying them.

To simplify it further, let’s take a normal screw with threads. While inserting a screw, the thread rotates for a particular number of times. Each rotation of this screw can be correlated to an equivalent axial movement, which is known as the lead or pitch of the screw.

If all the threads of the screw are made with a constant pitch, which is already known, the amount of axial movement generated can be easily traced on a scale. The micrometer screw gauge uses this principle to measure dimensions.

Complete Step By Step Answer:

For solving this question we need to know the screw-gauge or micrometer screw-gauge is a measuring instrument used for precision measurement. A measuring device used extensively in the mechanical engineering field, micrometer screw gauge is used for measuring extremely small dimensions. A screw-gauge can even measure dimensions smaller than those measured by Vernier calipers. Belonging to the family of calipers, micrometer screw-gauges also contain two different scales.

Now we will study about its constructions and parts:

A screw gauge consists of “U” shaped metallic structure, which is attached to a hollow cylinder tube on one end. The hollow tube has a uniformly threaded nut inside it. A long stud with a plane phase is fitted into this nut. Exactly on the opposite side of this nut and on the other end of the U shaped frame, a smaller stud with a plane face is also attached. Faces of both the studs are exactly parallel to each other.

This U shaped metallic structure is known as the frame of micrometer screw gauge. The smaller stud is known as a frame of micrometer screw gauge. The smaller stud is known as the anvil and the longer one is known as spindle. The anvil is a fixed part of the device, whereas the spindle moves as and when the head is moved. The frame carries both the anvil and barrel, and is also heavier than the rest parts. The object to be measured is held between the anvil and the spindle.

The barrel or sleeve connects the frame to a cylindrical tube. . It is a non-movable part of the screw gauge and has a scale inscribed over it which is the main scale of the device. Moreover, it also carries the most important part of the micrometer- the screw.

The screw is the heart of the micrometer and is located inside the barrel. The screw converts small dimensions into measurable distance using a scale. The thimble or head is the end of the cylindrical tube and is turned to move and adjust the spindle. The thimble carries the vernier or secondary scale. There is one more part called the ratchet which is provided at the end of the tube. The ratchet is a kind of limiting device which applies a pressure by slipping at a predetermined torque and thus prevents the spindle from moving further. Some screw gauges also consist of locking devices which hold the scales at a particular position for prevent any kind of error while taking readings.

Thus the main parts of a micrometer screw gauge are:

-Frame

-Anvil

-Spindle

-Sleeve

-Thimble

-Ratchet

-Screw

Now we will study these one by one:

Frame: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Anvil: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Spindle: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Thimble: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Sleeve: The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used. It is the fixed part mounted at one end of the frame exactly parallel to the moving spindle which moves towards it.

Ratchet: The hollow cylinder leads to a ratchet which is meant for fine adjustment. The U frame consists of a flat end known as stud and a screw on the other side. This screw can be moved inside the nut by fitted in the U frame by rotating the hollow cylinder called the thimble. This is called the main scale.

Screw: Micrometer screw gauge is a device incorporating a calibrated screw is widely used for precise measurement of components in the manufacturing of mechanical parts. The body used to hold the anvil and barrel firmly in their place is called a frame, in micrometer screw gauges, thick C shaped frames are used.

Hence our option A is correct.

Note:

Now we will be studying about the working principle of it:

Micrometer Screw gauge works on the simple principle of converting small distances into larger ones by measuring the rotation of the screw. This “screw” principle facilitates reading of smaller distances on a scale after amplifying them.

To simplify it further, let’s take a normal screw with threads. While inserting a screw, the thread rotates for a particular number of times. Each rotation of this screw can be correlated to an equivalent axial movement, which is known as the lead or pitch of the screw.

If all the threads of the screw are made with a constant pitch, which is already known, the amount of axial movement generated can be easily traced on a scale. The micrometer screw gauge uses this principle to measure dimensions.

Recently Updated Pages

Master Class 11 Computer Science: Engaging Questions & Answers for Success

Master Class 11 Business Studies: Engaging Questions & Answers for Success

Master Class 11 Economics: Engaging Questions & Answers for Success

Master Class 11 English: Engaging Questions & Answers for Success

Master Class 11 Maths: Engaging Questions & Answers for Success

Master Class 11 Biology: Engaging Questions & Answers for Success

Trending doubts

One Metric ton is equal to kg A 10000 B 1000 C 100 class 11 physics CBSE

There are 720 permutations of the digits 1 2 3 4 5 class 11 maths CBSE

Discuss the various forms of bacteria class 11 biology CBSE

Draw a diagram of a plant cell and label at least eight class 11 biology CBSE

State the laws of reflection of light

Explain zero factorial class 11 maths CBSE