To measure radius of a wire suitable measuring device is:

A. Screw gauge

B. Pipette

C. Metre scale

D. Pendulum

Answer

559.2k+ views

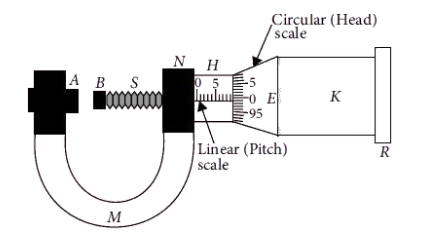

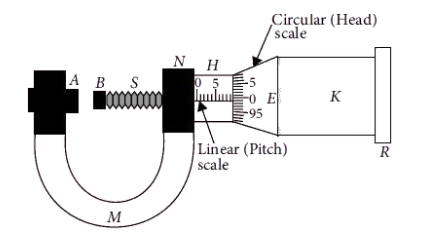

Hint: Screw gauge is used to calculate radius of thin wire, plates sheets paper etc. because it has more precision than any of the normal measuring devices. The working, uses and diagrams of screw gauge will be discussed in the below sections.

Formula used:

In screw gauge least count is calculated as $L.C=\dfrac{p}{N}$

Here, $L.C$(least count), $p$(pitch) and $N$(No. of divisions on circular scale)

Complete solution:

The pitch of the screw gauge is defined as the total distance covered by the screw during one complete rotation, it can be rotated in clockwise or anti-clockwise direction by which screw will move in forward or backward direction accordingly.

If a screw gauge having a pitch of 1 mm and 100 divisions on circular scale than least count will be,

$L.C=\dfrac{1mm}{100}=0.01mm$.

To calculate radius of wire we need a wire, screw gauge and metre scale. To take reading from the linear scale note the mark on the linear scale which is close enough to the edge of the circular scale, similarly for circular scale reading note the division on the circular scale coinciding with the main scale reading.

So, by the above statements our required answer is option A) Screw gauge.

Additional information:

While measuring the radius of wire using screw gauge it’s possible to have an error in measurement due to imperfect device or any other factor. One of the errors is called zero error which is defined as, when two studs A and B (refer diagram) bought in contact and if the zero of the circular scale does not coincide with the reference line of main scale known as zero error which can be of two type positive zero error and negative zero error.

Note:

While measuring the radius of wire carefully observe the zero error in the screw gauge and can be resolved by adding or subtracting it according to the positive or negative zero error. The least count of screw gauge is very low so carefully do the calculation without any human error.

Formula used:

In screw gauge least count is calculated as $L.C=\dfrac{p}{N}$

Here, $L.C$(least count), $p$(pitch) and $N$(No. of divisions on circular scale)

Complete solution:

The pitch of the screw gauge is defined as the total distance covered by the screw during one complete rotation, it can be rotated in clockwise or anti-clockwise direction by which screw will move in forward or backward direction accordingly.

If a screw gauge having a pitch of 1 mm and 100 divisions on circular scale than least count will be,

$L.C=\dfrac{1mm}{100}=0.01mm$.

To calculate radius of wire we need a wire, screw gauge and metre scale. To take reading from the linear scale note the mark on the linear scale which is close enough to the edge of the circular scale, similarly for circular scale reading note the division on the circular scale coinciding with the main scale reading.

So, by the above statements our required answer is option A) Screw gauge.

Additional information:

While measuring the radius of wire using screw gauge it’s possible to have an error in measurement due to imperfect device or any other factor. One of the errors is called zero error which is defined as, when two studs A and B (refer diagram) bought in contact and if the zero of the circular scale does not coincide with the reference line of main scale known as zero error which can be of two type positive zero error and negative zero error.

Note:

While measuring the radius of wire carefully observe the zero error in the screw gauge and can be resolved by adding or subtracting it according to the positive or negative zero error. The least count of screw gauge is very low so carefully do the calculation without any human error.

Recently Updated Pages

Master Class 11 Computer Science: Engaging Questions & Answers for Success

Master Class 11 Business Studies: Engaging Questions & Answers for Success

Master Class 11 Economics: Engaging Questions & Answers for Success

Master Class 11 English: Engaging Questions & Answers for Success

Master Class 11 Maths: Engaging Questions & Answers for Success

Master Class 11 Biology: Engaging Questions & Answers for Success

Trending doubts

One Metric ton is equal to kg A 10000 B 1000 C 100 class 11 physics CBSE

There are 720 permutations of the digits 1 2 3 4 5 class 11 maths CBSE

Discuss the various forms of bacteria class 11 biology CBSE

Draw a diagram of a plant cell and label at least eight class 11 biology CBSE

State the laws of reflection of light

Explain zero factorial class 11 maths CBSE