How Does a Single Fixed Pulley Work in Everyday Life?

A single fixed pulley is a classic example of a simple machine in physics. It is essential for JEE aspirants to understand its principles, applications, and problem-solving strategies. Let’s explore the concept in detail.

Understanding Basic Pulley Mechanics

A pulley is a wheel on an axle or shaft, designed to support movement and change the direction of force using a taut cable or rope.

Historically, pulleys date back to ancient Egypt and Mesopotamia. They were invaluable for lifting heavy loads with less effort, especially in well-water systems.

In modern physics, pulleys demonstrate the fundamental concepts of force and equilibrium. They play a key role in mechanical advantage and efficiency analyses.

Classifying Pulley Types

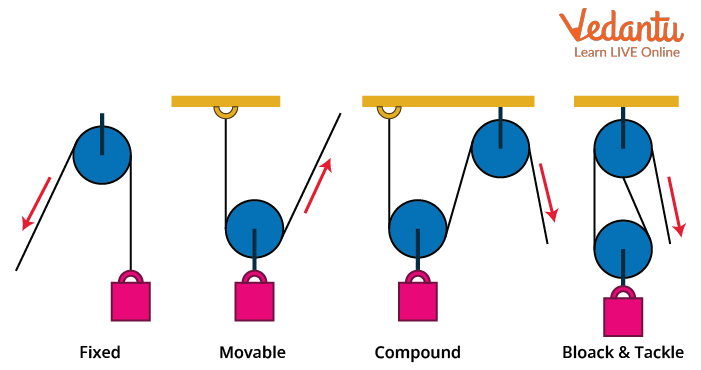

Pulleys exist in various forms to meet different mechanical needs. Their classification depends on configuration and motion characteristics.

- Fixed pulley: attached to a stationary point or support

- Movable pulley: attached to the load and moves with it

- Compound pulley: connects fixed and movable pulleys together

- Cone pulley: series of pulleys of different diameters stacked

- Block and tackle: system of multiple pulleys for greater advantage

Each type offers unique advantages. The single fixed pulley, being the simplest, is fundamental in understanding force direction change.

What Is a Single Fixed Pulley?

A single fixed pulley is a type of pulley anchored at a fixed point, usually above the user, allowing the rope to move freely over its groove.

When you use a single fixed pulley, it does not change the amount of effort needed to lift a load. Instead, it only changes the direction of your applied force.

For example, drawing water from a well using a bucket is a classic single fixed pulley scenario. This device lets you pull downward to raise the bucket upward, making the job more ergonomic.

The single fixed pulley is widely used because it offers simplicity, reliability, and helps users pull heavy loads in a more convenient direction.

Single Fixed Pulley: Key Physics Principle

The critical principle in a single fixed pulley system is that the tension on both sides of the rope is equal (ideal case, neglecting friction).

Hence, the force required to lift the object (Effort) equals the weight of the object (Load) itself in such an ideal pulley.

Mechanical advantage (MA) measures how much a machine amplifies force. It is calculated as:

$MA = \dfrac{\text{Load}}{\text{Effort}}$

For a single fixed pulley, since Load = Effort, we get:

$MA = 1$

This means a single fixed pulley does not increase force, but only changes its direction for easier application.

Single Fixed vs Single Movable Pulley: Comparison

| Single Fixed Pulley | Single Movable Pulley |

|---|---|

| Changes direction of force only | Reduces effort required |

| Mechanical advantage is 1 | Mechanical advantage is 2 |

| Axle is stationary | Pulley moves with the load |

| Example: well pulley | Example: construction hoist |

Understanding the distinction helps in designing efficient machines for Work Energy And Power applications.

Single Fixed Pulley: Real-World Analogies

Picture lifting a heavy flag on a flagpole using a rope over a pulley at the top. You pull downward, but the flag rises up easily.

The ergonomic benefit enables users to apply their own weight while pulling, making tasks safer and less tiring.

Farmers, window cleaners, and engineers commonly employ single fixed pulleys for practical convenience in lifting or positioning loads.

Students often first observe pulley systems in school laboratories, and mastering their physics prepares them for advanced mechanics like Rotational Motion.

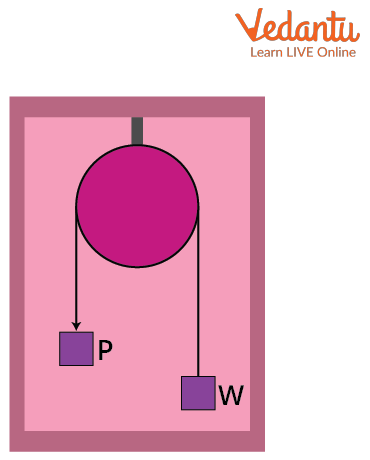

Mechanics: Forces Acting in a Single Fixed Pulley

The core forces in the system are: the load (downwards), the effort (upwards, via the rope), and the reaction at the pulley’s axle.

Assume negligible friction and a massless rope; the force in both rope segments equals the load's weight.

This demonstration is frequently tested in JEE exam questions, especially those integrating analysis with Torque And Equilibrium.

How to Draw a Single Fixed Pulley Diagram

To draw a single fixed pulley diagram, sketch a circular wheel fixed atop a support. Draw a string passing over it with the load on one end, effort on the other.

Label the direction of each force—downward for load, upward for effort—to clearly represent how force directions are reversed.

This skill helps answer JEE questions demanding visual explanations or identifying force interactions in a Moment Of Inertia context.

Numerical Example: Single Fixed Pulley Calculation

A student lifts a 10 kg bucket of water from a well using a single fixed pulley. Find the effort applied if the system is ideal (ignore friction and mass of rope).

Known values: Mass ($m$) = 10 kg, Acceleration due to gravity ($g$) = 9.8 m/s$^2$.

Weight, $W = m \times g$

$W = 10 \times 9.8$

$W = 98$ N

For an ideal single fixed pulley, Effort = Load, so Effort = 98 N. The student must apply a force of 98 N upward to lift the bucket.

Solved Example for Practice

Practice: If a person wants to lift a 15 kg object using a single fixed pulley, what will be the minimum effort required (take $g = 10$ m/s$^2$)? Ignore all friction.

Typical Mistakes in Single Fixed Pulley Problems

- Confusing mechanical advantage with effort reduction

- Forgetting to account for friction losses in real scenarios

- Not drawing direction arrows clearly on diagrams

- Miscalculating tension if pulley or rope has mass

Carefully read questions and apply the principle that, ideally, effort equals load.

Most Important Applications of Single Fixed Pulley

- Drawing water from wells and lifting buckets

- Flagpole mechanisms for raising or lowering flags

- Window cleaning scaffold operation in buildings

- Rigging sails on boats for direction control

Its simplicity makes it essential in numerous daily tasks and introductory physics experiments.

Related Physics Topics for Further Study

Explore these related concepts for JEE mastery:

- Torque and rotational equilibrium

- Work, energy, and power

- Centrifugal and centripetal forces

- Moment of inertia fundamentals

- Linear and angular momentum

- Advanced rotational motion principles

FAQs on What Is a Single Fixed Pulley?

1. What is a single fixed pulley?

A single fixed pulley is a simple machine made of a wheel and a fixed axle, used to change the direction of force applied to lift a load.

Main features include:

- The pulley is fixed to a support and does not move with the load.

- It helps in lifting objects vertically by pulling the rope downwards.

- Mechanical advantage is 1; it does not multiply force but makes lifting easier by changing force direction.

- Commonly used in flagpoles, wells, and window blinds.

2. How does a single fixed pulley work?

A single fixed pulley works by redirecting the applied force, allowing users to lift a load by pulling the rope down.

Steps:

- The pulley stays stationary while the rope moves.

- When you pull one end of the rope downward, the load attached to the other end rises upward.

- This setup makes it easier to use your body weight and gravity for lifting.

3. What is the mechanical advantage of a single fixed pulley?

The mechanical advantage of a single fixed pulley is 1.

Key points:

- It does not multiply the input force.

- The effort applied equals the load lifted, ignoring friction.

- The main benefit is changing the direction of the force, not increasing strength.

4. What are the uses of a single fixed pulley?

Single fixed pulleys are widely used in daily life to make lifting easier.

Common uses include:

- Raising flags on flagpoles

- Drawing water from wells

- Hoisting sails on ships

- Opening or closing window blinds

5. Why is the mechanical advantage of a single fixed pulley always 1?

The mechanical advantage of a single fixed pulley is always 1 because the force applied to lift the load is equal to the force needed to move the load (ignoring friction).

This means:

- There is no multiplication of force.

- The pulley simply changes the force direction.

- It helps in applying force more conveniently but does not reduce effort needed.

6. What are the differences between a single fixed pulley and a single movable pulley?

Single fixed pulleys and single movable pulleys differ in several ways:

- Fixed pulley: The pulley is fixed and only changes direction of force (mechanical advantage = 1).

- Movable pulley: The pulley moves with the load and multiplies force (mechanical advantage = 2).

- With a movable pulley, less effort is needed than the load's weight.

7. What are the advantages and disadvantages of using a single fixed pulley?

The single fixed pulley offers both benefits and limitations.

Advantages:

- Easy to use and set up

- Changes force direction, making lifting convenient

- Reduces strain on the body by allowing downward pulling

- Does not multiply force (mechanical advantage = 1)

- Does not reduce the actual effort needed to lift

8. Can a single fixed pulley be used to lift heavy loads efficiently?

A single fixed pulley can help lift heavy loads by changing the direction of effort, but it does not reduce the force needed. For very heavy loads, combining with other pulleys is more efficient.

Key points:

- Only changes force direction, doesn't reduce effort

- Multiple pulleys or pulley systems are better for lifting very heavy weights

9. What is the function of the axle in a pulley?

The axle in a pulley serves as the fixed central support around which the pulley wheel rotates.

Main functions:

- Holds the pulley securely in place

- Allows the wheel to rotate smoothly as the rope moves

- Ensures load is properly supported

10. Why do we use a single fixed pulley if it does not provide mechanical advantage?

We use a single fixed pulley mainly to make lifting tasks easier by changing the force direction, not to multiply force.

Benefits include:

- Allows user to pull downward, using body weight and gravity

- Makes lifting tasks more comfortable and practical

- Improves lifting efficiency for lighter loads