Why is Bakelite used for making electrical switches?

Answer

521.1k+ views

Hint: Let us first learn about Bakelite. Bakelite is a thermosetting plastic. It is a phenolic resin or a condensation polymer. It is made by the condensation reaction of phenol with formaldehyde forming a phenol-formaldehyde resin. It is the same chemical as polyox benzyl methylene glycol anhydride.

Complete step-by-step solution:

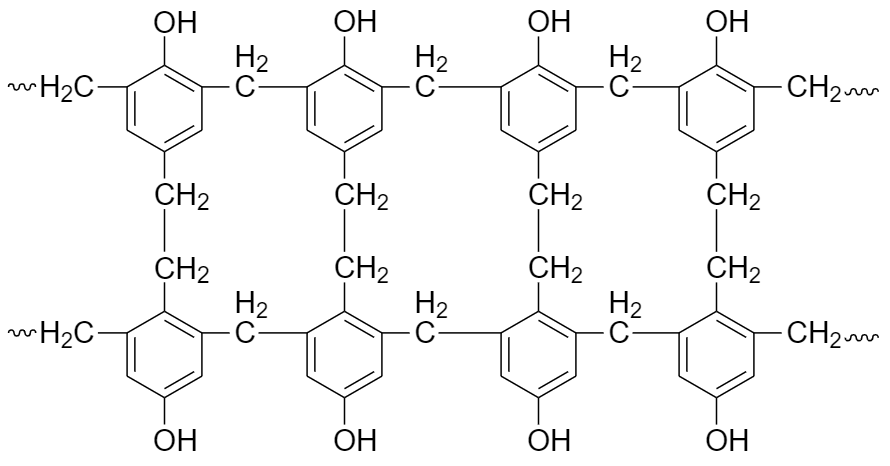

The structure of Bakelite is as follows

Bakelite is commonly named as the material having a thousand uses. This is because of its desirable properties like

1. It can be made into different bright colors even though it usually has amber or brown color.

2. Upon heating, it becomes malleable and liquefiable. But as soon as it cools, it becomes permanently rigid and hard and hence it is a thermosetting plastic.

3. It can be used to make various products as it can be easily molded.

4. It shows high resistance towards chemical action, electricity, and heat.

5. Its dielectric constant is in the range of 4.4 to 5.4.

Hence, due to its high resistance towards heat and electricity, it is a good insulator and can be used to make non-conducting parts of electrical devices like sockets and switches.

Note:

It should be noted that the properties like the strength of Bakelite can be enhanced using fillers such that it can be used for various things. Fillers like mica, gypsum, pulp, cotton, wood flour, asbestos, etc., can be added to molding resins like Bakelite. The enhancement in some of the properties are observed as follows

1. Increased strength and toughness

2. Better chemical, electrical and thermal resistance.

3. Enhanced moldability.

4. Color changes.

Complete step-by-step solution:

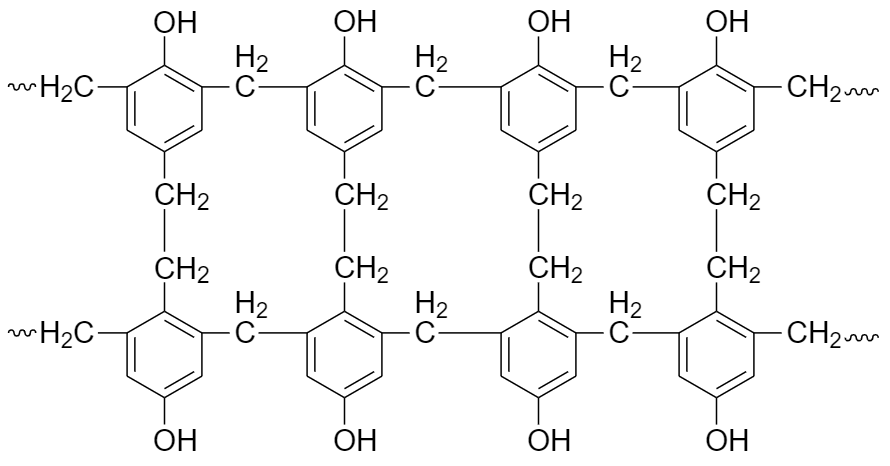

The structure of Bakelite is as follows

Bakelite is commonly named as the material having a thousand uses. This is because of its desirable properties like

1. It can be made into different bright colors even though it usually has amber or brown color.

2. Upon heating, it becomes malleable and liquefiable. But as soon as it cools, it becomes permanently rigid and hard and hence it is a thermosetting plastic.

3. It can be used to make various products as it can be easily molded.

4. It shows high resistance towards chemical action, electricity, and heat.

5. Its dielectric constant is in the range of 4.4 to 5.4.

Hence, due to its high resistance towards heat and electricity, it is a good insulator and can be used to make non-conducting parts of electrical devices like sockets and switches.

Note:

It should be noted that the properties like the strength of Bakelite can be enhanced using fillers such that it can be used for various things. Fillers like mica, gypsum, pulp, cotton, wood flour, asbestos, etc., can be added to molding resins like Bakelite. The enhancement in some of the properties are observed as follows

1. Increased strength and toughness

2. Better chemical, electrical and thermal resistance.

3. Enhanced moldability.

4. Color changes.

Recently Updated Pages

Master Class 12 Economics: Engaging Questions & Answers for Success

Master Class 12 Physics: Engaging Questions & Answers for Success

Master Class 12 English: Engaging Questions & Answers for Success

Master Class 12 Social Science: Engaging Questions & Answers for Success

Master Class 12 Maths: Engaging Questions & Answers for Success

Master Class 12 Business Studies: Engaging Questions & Answers for Success

Trending doubts

Why cannot DNA pass through cell membranes class 12 biology CBSE

Draw a neat and well labeled diagram of TS of ovary class 12 biology CBSE

In a human foetus the limbs and digits develop after class 12 biology CBSE

AABbCc genotype forms how many types of gametes a 4 class 12 biology CBSE

Differentiate between homogeneous and heterogeneous class 12 chemistry CBSE

The correct structure of ethylenediaminetetraacetic class 12 chemistry CBSE