Describe slip rings.

Answer

515.1k+ views

Hint: A slip ring transfers electrical signals and power over a rotating interface utilizing sliding electrical contacts. These contacts are generally a stationary brush, a rotating ring, or a wiper that pushes along the ring surface through rotation.

Complete step-by-step solution:

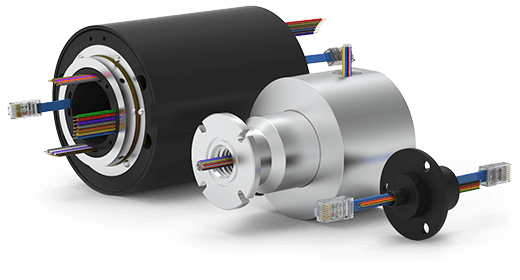

Slip rings — also assigned to rotating electrical joints, collector rings, and electric swivels — can carry power, electrical signals, rotating components, or data between a stationary component. The picture of a slip ring will depend on its purposes — conveying data, for example, needs a slip ring with larger bandwidth and stabler EMI reduction than one that carries power — but the fundamental components are a rotating ring and stable brushes.

A slip ring is, put, a primary component of a motor, and with that announced, it is safe to say any mechanical body we utilize with a motor inside is most possible to have it. Slip rings are utilized in a broad range of motors, from a wind turbine to entertainment park trips and vehicles to a relatively simple brushed DC motor; they are in other places than we know.

A slip ring is an electrochemical machine that enables the transmission of signals and energy from a fixed to a rotating construction such as space satellites, sensor gimbals, radar antenna, and electro-optics. They are utilized in those electromechanical systems, which mainly involve turns while transporting out power transmission. It assists in making the operation more uncomplicated, and we can understand the mechanical performance getting raised. The slip rings are also recognized as the commutator and electric slip rings. It provides an infinite amount of rotations of the associated object.

Slip rings are usually made of electrically conductive substances, such as copper, and fitted to a rotating motor handle with connective wiring running into the motors from them. The element which transfers the power to the slip ring is termed a 'brush'; it is usually formed with a composite of carbon and copper and regularly attains the slip-rings, hence the name 'brush' as they continually brush upon the slip-rings. This regular touch conducts the energy flow.

Note: Slip rings contain a metal contact brush and fixed graphite, which runs on the external diameter of the metal ring. The current that is set passes through ways from metal brush to the element ring. If there is a requirement for one or more circuits, the extra brush is joined along the turning axis. Rings and brushes are permanent and fixed.

Complete step-by-step solution:

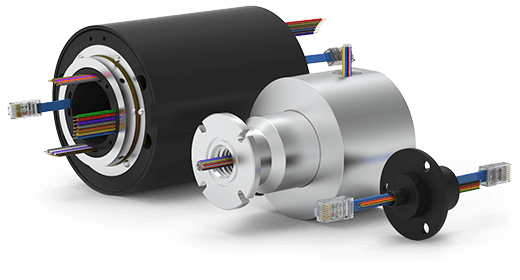

Slip rings — also assigned to rotating electrical joints, collector rings, and electric swivels — can carry power, electrical signals, rotating components, or data between a stationary component. The picture of a slip ring will depend on its purposes — conveying data, for example, needs a slip ring with larger bandwidth and stabler EMI reduction than one that carries power — but the fundamental components are a rotating ring and stable brushes.

A slip ring is, put, a primary component of a motor, and with that announced, it is safe to say any mechanical body we utilize with a motor inside is most possible to have it. Slip rings are utilized in a broad range of motors, from a wind turbine to entertainment park trips and vehicles to a relatively simple brushed DC motor; they are in other places than we know.

A slip ring is an electrochemical machine that enables the transmission of signals and energy from a fixed to a rotating construction such as space satellites, sensor gimbals, radar antenna, and electro-optics. They are utilized in those electromechanical systems, which mainly involve turns while transporting out power transmission. It assists in making the operation more uncomplicated, and we can understand the mechanical performance getting raised. The slip rings are also recognized as the commutator and electric slip rings. It provides an infinite amount of rotations of the associated object.

Slip rings are usually made of electrically conductive substances, such as copper, and fitted to a rotating motor handle with connective wiring running into the motors from them. The element which transfers the power to the slip ring is termed a 'brush'; it is usually formed with a composite of carbon and copper and regularly attains the slip-rings, hence the name 'brush' as they continually brush upon the slip-rings. This regular touch conducts the energy flow.

Note: Slip rings contain a metal contact brush and fixed graphite, which runs on the external diameter of the metal ring. The current that is set passes through ways from metal brush to the element ring. If there is a requirement for one or more circuits, the extra brush is joined along the turning axis. Rings and brushes are permanent and fixed.

Recently Updated Pages

Master Class 12 Economics: Engaging Questions & Answers for Success

Master Class 12 Physics: Engaging Questions & Answers for Success

Master Class 12 English: Engaging Questions & Answers for Success

Master Class 12 Social Science: Engaging Questions & Answers for Success

Master Class 12 Maths: Engaging Questions & Answers for Success

Master Class 12 Business Studies: Engaging Questions & Answers for Success

Trending doubts

Which are the Top 10 Largest Countries of the World?

What are the major means of transport Explain each class 12 social science CBSE

Draw a labelled sketch of the human eye class 12 physics CBSE

Why cannot DNA pass through cell membranes class 12 biology CBSE

Differentiate between insitu conservation and exsitu class 12 biology CBSE

Draw a neat and well labeled diagram of TS of ovary class 12 biology CBSE