Draw the diagrams showing zero errors of a Screw Gauge.

(a) No zero error

(b) Negative zero error

(c) Positive zero error

Answer

598.8k+ views

Hint:

We measure the number of turns and the final count to determine the distance travelled by the screw of the Screw Gauge. If we close the gauge completely, there can be three situations depending on the relative position of zeros.

Complete step-by-step answer:

There are several measuring instruments in Physics. Screw gauge is generally used to measure diameters of very thin wires. Let’s understand the measurement technique of the screw gauge.

Least count is a quantity which is defined as the distance moved by the tip of the screw when we turn the head scale by one division. Least count of the screw gauge is fixed for each instrument and it is given to us.

Pitch is another quantity which is fixed for the screw gauge. It is the distance moved by the spindle if we rotate the head scale by one complete rotation.

We take the readings at the start and the final position. The difference in the readings gives us the length.

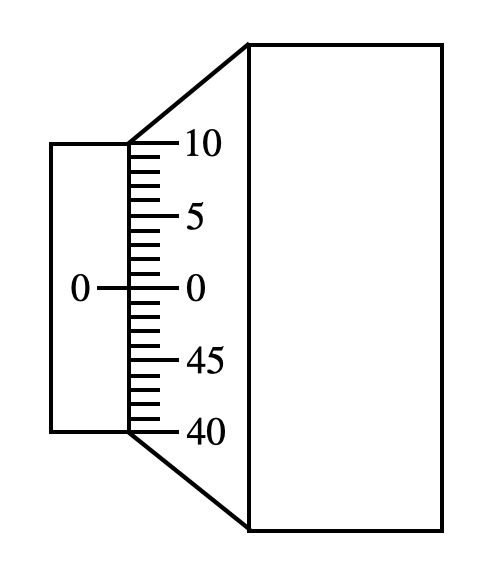

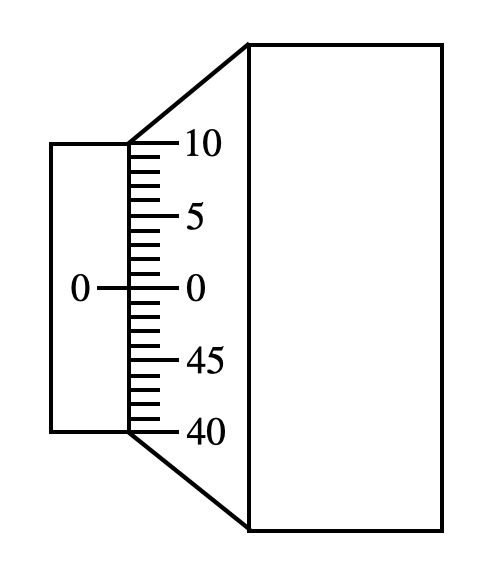

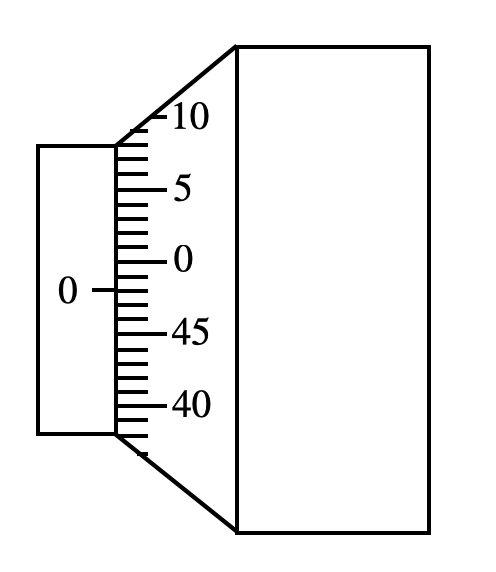

(a) As we take readings relative to a starting position, we are prone to make errors if the two scales are not properly aligned. If we touch the tip to the fixed portion, then the position of the scale should be like the following diagram,

As you can see in the diagram, the 0 touches the marking of the other 0 markings. This is called No zero error.

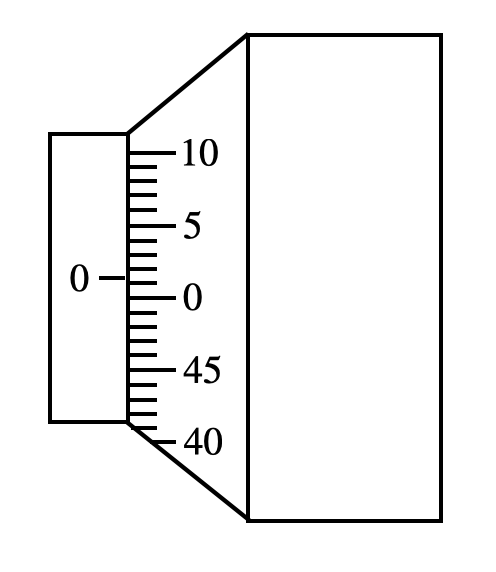

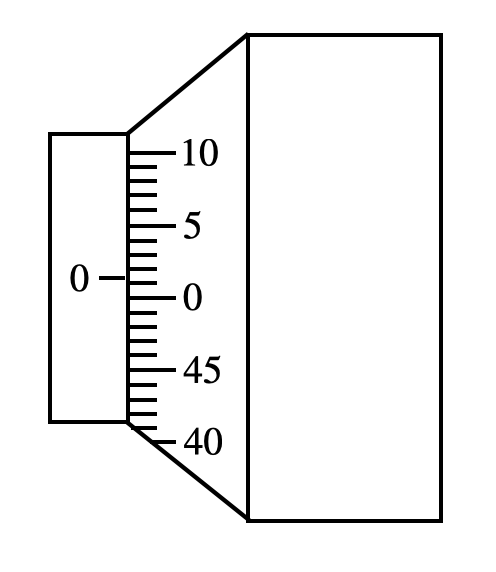

(b) The following diagram shows a positive zero error.

As you can see the 0 markings of the scale is slightly below the other 0 markings. This is called a positive zero error. In case of positive zero error, you need to subtract the error from the final result.

(c) Negative zero error is shown in the following figure-

In Negative zero error, you have to add the error to the final result to get the correct measurement.

Note:

It is important for the experimenter to check for the zero error in a screw gauge before starting the experiment. One should also be careful of the parallax error. You need to see the readings perpendicular to the scale so that you can see the correct reading.

We measure the number of turns and the final count to determine the distance travelled by the screw of the Screw Gauge. If we close the gauge completely, there can be three situations depending on the relative position of zeros.

Complete step-by-step answer:

There are several measuring instruments in Physics. Screw gauge is generally used to measure diameters of very thin wires. Let’s understand the measurement technique of the screw gauge.

Least count is a quantity which is defined as the distance moved by the tip of the screw when we turn the head scale by one division. Least count of the screw gauge is fixed for each instrument and it is given to us.

Pitch is another quantity which is fixed for the screw gauge. It is the distance moved by the spindle if we rotate the head scale by one complete rotation.

We take the readings at the start and the final position. The difference in the readings gives us the length.

(a) As we take readings relative to a starting position, we are prone to make errors if the two scales are not properly aligned. If we touch the tip to the fixed portion, then the position of the scale should be like the following diagram,

As you can see in the diagram, the 0 touches the marking of the other 0 markings. This is called No zero error.

(b) The following diagram shows a positive zero error.

As you can see the 0 markings of the scale is slightly below the other 0 markings. This is called a positive zero error. In case of positive zero error, you need to subtract the error from the final result.

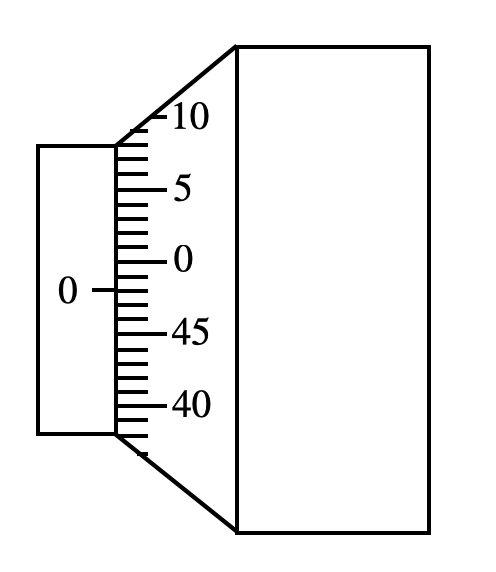

(c) Negative zero error is shown in the following figure-

In Negative zero error, you have to add the error to the final result to get the correct measurement.

Note:

It is important for the experimenter to check for the zero error in a screw gauge before starting the experiment. One should also be careful of the parallax error. You need to see the readings perpendicular to the scale so that you can see the correct reading.

Recently Updated Pages

Master Class 11 Computer Science: Engaging Questions & Answers for Success

Master Class 11 Business Studies: Engaging Questions & Answers for Success

Master Class 11 Economics: Engaging Questions & Answers for Success

Master Class 11 English: Engaging Questions & Answers for Success

Master Class 11 Maths: Engaging Questions & Answers for Success

Master Class 11 Biology: Engaging Questions & Answers for Success

Trending doubts

One Metric ton is equal to kg A 10000 B 1000 C 100 class 11 physics CBSE

There are 720 permutations of the digits 1 2 3 4 5 class 11 maths CBSE

Discuss the various forms of bacteria class 11 biology CBSE

Draw a diagram of a plant cell and label at least eight class 11 biology CBSE

State the laws of reflection of light

Explain zero factorial class 11 maths CBSE