The flux used in the extraction of iron from haematite ore in the blast furnace is:

A.Limestone

B.Silica

C.Coke

D.Quartz

Answer

576.9k+ views

Hint:Extraction is one of the main processes in metallurgy in which impurities are removed from an ore to extract pure metal. Flux is a cleansing agent which helps in removing the impurities present in the metal .

Complete step by step answer:

When iron is extracted from the haematite ore $\left( {F{e_2}{O_3}} \right)$ , then this process is known as iron extraction blast furnace metallurgy.

There are basically three major steps by which iron is extracted and purified. So we will see what each process means in details as follows:

A.Concentration of ore

B.Extraction of metal from the concentrated ore

C.Purification of metal

A.Concentration of ore:

-Extraction of iron from its ore is quite a long process which includes concentration of ore through the process of roasting and calcination.

Whatever impurities are present that will be removed by the process of concentration.

First we will see what is meant by calcination and roasting.

-Calcination: It is the process where an ore is converted to oxide by heating it strongly.

It takes place in the absence of air or in controlled supply.

-The word calcination was derived from the Latin word ‘calcinare’ which means ‘to burn lime’.

-During this process, hydroxides and carbonates are converted into their respective oxides.

-It also separates moisture and volatile impurities.

-There is a reaction where calcium carbonate also known as limestone gets converted to calcium oxide (lime). The reaction is given below as follows:

$CaC{O_3} \to CaO + C{O_2}$

-It separates moisture and volatile impurities.

-The products obtained by this process are known as calcines.

-Roasting: This process is carried out by converting ore to oxide by heating it above melting point in the presence of excess air.

-This process is mostly used to convert sulphide ores into oxides.

-Even in this process moisture and other volatile impurities are removed.

-This process goes through various steps such as oxidation, reduction, chlorination, sulfation and pyrohydrolysis.

-There is a reaction in which zinc sulphide gets converted to its oxide as follows:

$2ZnS + 3{O_2} \to 2ZnO + C{O_2}$ .

-One of the major drawbacks of this process is that it creates lots of air pollution as large amounts of sulphide is released and harms the environment.

B.Extraction of ore from concentrated ore:

-This process is carried out in the blast furnace.

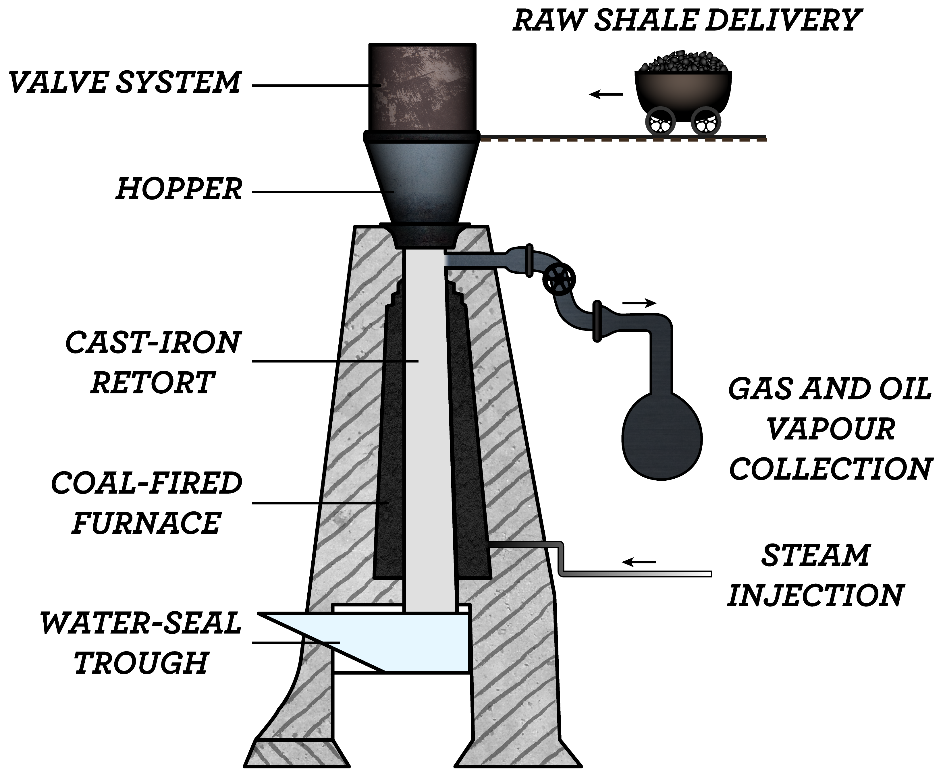

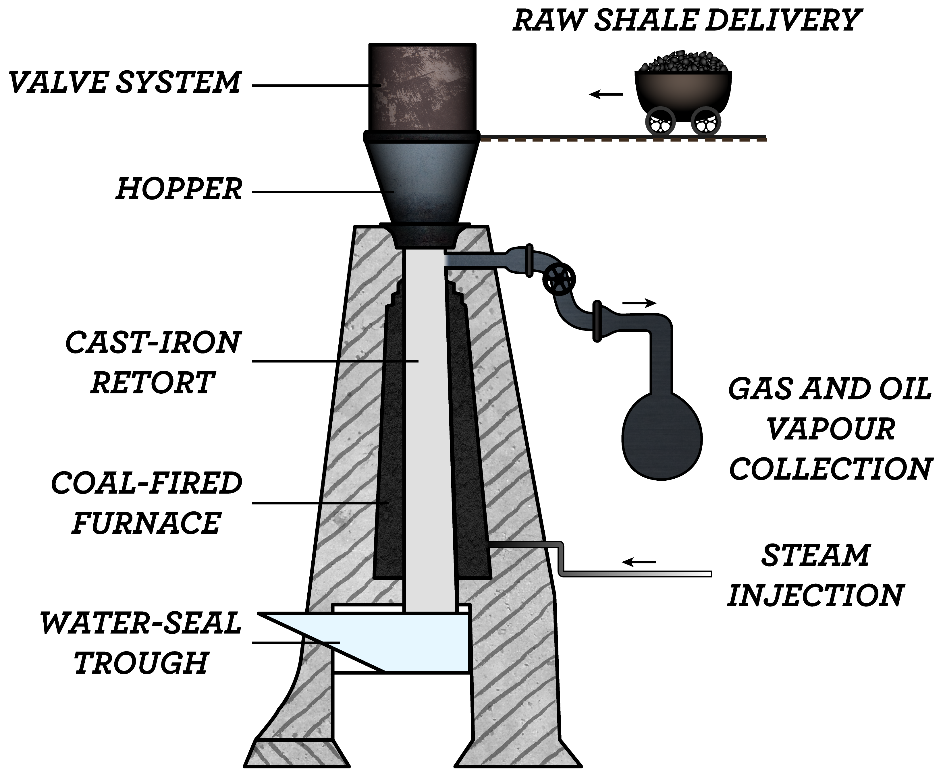

-The diagram is given below:

-Blast furnace is a large, giant steel stack lined parallel with refractory brick.

-So in this concentrated ore, limestone and ore are put in from the top part of the blast furnace.

-All the ingredients are crushed and mixed and then put on a hopper.

-Later hot air is blown from the top and the coke gets burned to attain the temperature of about $2200K$ .

-At this temperature coke reacts with the oxygen that is present in hot air and gets converted to carbon monoxide $\left( {CO} \right)$ .

-The temperature in the upper part of the furnace is low as compared to bottom.

-So here haematite and magnetite ores get reduced to ferrous oxide.

-The reaction that takes in blast furnace are as follows:

\[3F{e_2}{O_3} + CO \to 2F{e_3}{O_4} + C{O_2}\]

\[F{e_3}{O_4} + 4CO \to 3Fe + 4C{O_2}\]

\[F{e_2}{O_3} + CO \to 2FeO + C{O_2}\]

-These reactions take place in the upper part of the furnace.

-The reactions that take place in the lower part are as follows:

$C + C{O_2} \to 2CO$

\[3FeO + C{O_2} \to Fe + C{O_2}\]

C.Purification:

-This is the last process where you get a purified form of iron.

-The purified form of iron is known as wrought iron.

-In this haematite reacts with cast iron to give purified iron. The reaction is given below:

\[F{e_2}{O_3} + 3C \to 2Fe + 3CO\] .

-Then limestone is added as a flux to create slag.

-Flux is basically a cleaning agent or a purifying agent to remove the impurities present in the metal.

-Slag is a by-product that is formed with the fluxing agent that is limestone.

Later on this slag can be separated easily from purified iron.

So, limestone is used as a flux in the purification process of iron from haematite ore.

Therefore, the correct answer is a) Limestone.

Note:

Do not get confused with the molten iron and molten slag. Molten iron is the liquid state obtained of iron whereas molten slag is the impurity that is found in molten iron. This molten slag is separated from the impurity with the help of limestone.

Complete step by step answer:

When iron is extracted from the haematite ore $\left( {F{e_2}{O_3}} \right)$ , then this process is known as iron extraction blast furnace metallurgy.

There are basically three major steps by which iron is extracted and purified. So we will see what each process means in details as follows:

A.Concentration of ore

B.Extraction of metal from the concentrated ore

C.Purification of metal

A.Concentration of ore:

-Extraction of iron from its ore is quite a long process which includes concentration of ore through the process of roasting and calcination.

Whatever impurities are present that will be removed by the process of concentration.

First we will see what is meant by calcination and roasting.

-Calcination: It is the process where an ore is converted to oxide by heating it strongly.

It takes place in the absence of air or in controlled supply.

-The word calcination was derived from the Latin word ‘calcinare’ which means ‘to burn lime’.

-During this process, hydroxides and carbonates are converted into their respective oxides.

-It also separates moisture and volatile impurities.

-There is a reaction where calcium carbonate also known as limestone gets converted to calcium oxide (lime). The reaction is given below as follows:

$CaC{O_3} \to CaO + C{O_2}$

-It separates moisture and volatile impurities.

-The products obtained by this process are known as calcines.

-Roasting: This process is carried out by converting ore to oxide by heating it above melting point in the presence of excess air.

-This process is mostly used to convert sulphide ores into oxides.

-Even in this process moisture and other volatile impurities are removed.

-This process goes through various steps such as oxidation, reduction, chlorination, sulfation and pyrohydrolysis.

-There is a reaction in which zinc sulphide gets converted to its oxide as follows:

$2ZnS + 3{O_2} \to 2ZnO + C{O_2}$ .

-One of the major drawbacks of this process is that it creates lots of air pollution as large amounts of sulphide is released and harms the environment.

B.Extraction of ore from concentrated ore:

-This process is carried out in the blast furnace.

-The diagram is given below:

-Blast furnace is a large, giant steel stack lined parallel with refractory brick.

-So in this concentrated ore, limestone and ore are put in from the top part of the blast furnace.

-All the ingredients are crushed and mixed and then put on a hopper.

-Later hot air is blown from the top and the coke gets burned to attain the temperature of about $2200K$ .

-At this temperature coke reacts with the oxygen that is present in hot air and gets converted to carbon monoxide $\left( {CO} \right)$ .

-The temperature in the upper part of the furnace is low as compared to bottom.

-So here haematite and magnetite ores get reduced to ferrous oxide.

-The reaction that takes in blast furnace are as follows:

\[3F{e_2}{O_3} + CO \to 2F{e_3}{O_4} + C{O_2}\]

\[F{e_3}{O_4} + 4CO \to 3Fe + 4C{O_2}\]

\[F{e_2}{O_3} + CO \to 2FeO + C{O_2}\]

-These reactions take place in the upper part of the furnace.

-The reactions that take place in the lower part are as follows:

$C + C{O_2} \to 2CO$

\[3FeO + C{O_2} \to Fe + C{O_2}\]

C.Purification:

-This is the last process where you get a purified form of iron.

-The purified form of iron is known as wrought iron.

-In this haematite reacts with cast iron to give purified iron. The reaction is given below:

\[F{e_2}{O_3} + 3C \to 2Fe + 3CO\] .

-Then limestone is added as a flux to create slag.

-Flux is basically a cleaning agent or a purifying agent to remove the impurities present in the metal.

-Slag is a by-product that is formed with the fluxing agent that is limestone.

Later on this slag can be separated easily from purified iron.

So, limestone is used as a flux in the purification process of iron from haematite ore.

Therefore, the correct answer is a) Limestone.

Note:

Do not get confused with the molten iron and molten slag. Molten iron is the liquid state obtained of iron whereas molten slag is the impurity that is found in molten iron. This molten slag is separated from the impurity with the help of limestone.

Recently Updated Pages

Master Class 12 Economics: Engaging Questions & Answers for Success

Master Class 12 Physics: Engaging Questions & Answers for Success

Master Class 12 English: Engaging Questions & Answers for Success

Master Class 12 Social Science: Engaging Questions & Answers for Success

Master Class 12 Maths: Engaging Questions & Answers for Success

Master Class 12 Business Studies: Engaging Questions & Answers for Success

Trending doubts

Which are the Top 10 Largest Countries of the World?

What are the major means of transport Explain each class 12 social science CBSE

Draw a labelled sketch of the human eye class 12 physics CBSE

What is a transformer Explain the principle construction class 12 physics CBSE

Why cannot DNA pass through cell membranes class 12 biology CBSE

Differentiate between insitu conservation and exsitu class 12 biology CBSE