Introduction to Spur Gears

Spur gears, also known as straight-cut gears, are the most basic type of gear. They are made up of a cylinder or disc with teeth that protrude radially. The tooth faces are straight and parallel to the axis of rotation when seen at 90 degrees from the shaft length.

Spur Gear

What is Spur Gear?

One of the most common forms of precision cylindrical gears is spur gears. These gears have a straightforward construction with straight, parallel teeth arranged around the circumference of a cylinder body with a central bore that fits over a shaft. The gear is machined with a hub in several forms, thickening the gear body around the bore without modifying the gear face.

What are the Types of Spur Gears?

Spur gears are split into two types: external and internal.

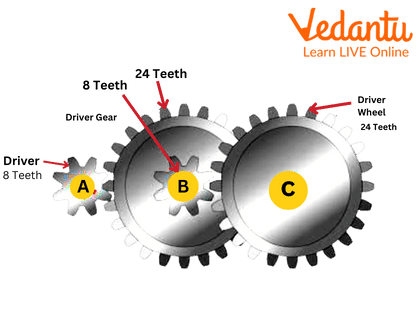

"External gears" are gears with teeth on the exterior of the cylinder. . An exterior gear can mesh with either an internal or external gear. When two exterior gears mesh, they spin in opposite directions

"Internal gears" are gears with teeth on the inside of the cylinder. Only an internal and external gear can mesh, and both gears must revolve in the same direction. Internal gear assemblies are more compact than external gear assemblies due to the close arrangement of shafts.

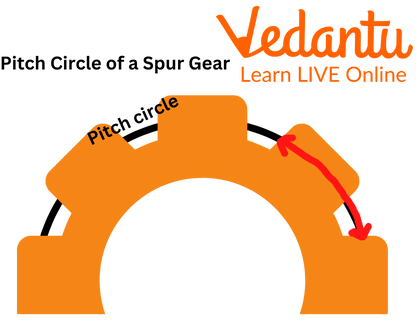

Pitch Circle

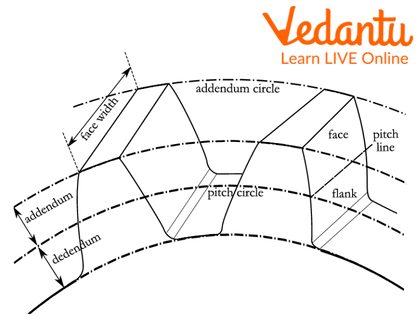

The pitch circle is the distance between the faces of two teeth. It separates the teeth of gear into the top of the tooth, the addendum, and the bottom of the tooth, the dedendum. Pitch circles between gears should be tangent to one another if a gear system is properly built.

Pitch Circle

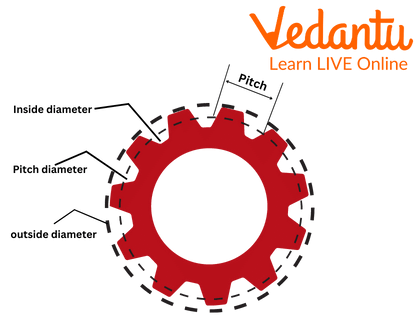

Diameter pitch - The diametral pitch of a gear is a function of its pitch circle and equals the number of teeth per inch. It determines what size and kind of gear are required to interlock with another gear.

Types of Spur Gear

Spur gears

Helical gears

Bevel gears

Worm gears

Spur Gear Diagram

Brief Explanation of Spur Gear

Spur Gear

Spur Gear Uses

Here are some applications of spur gear.

Tooling, allowing us the flexibility to fabricate standard or custom cold rolled spur gears designed to meet exact specifications across a wide range of industrial applications.

These spur gears are also used for industrial purposes - in the field of transmissions, speed reducers, conveyor systems, machining tools, etc.

Increasing and decreasing power - Spur gears are found in washing machines, blenders, clothes dryers, construction equipment, pumps, and conveyors and are used to enhance or decrease the torque or power on a device.

Road roller - A set of spur gears in a road roller converts the engine's fast rotating speed into the wheels' slow rotational speed. Because of this improvement, a road roller is able to move its heavy roller.

Spur Gear in Train

Solved Examples

1. What are the benefits of spur gear?

Ans: Simple design, precise and accuracy, low production cost, gear reliability, spur gear efficiency, straight teeth.

2. How to choose the right spur gears?

Ans: Selecting by torque and speed, identifying through pitch, idler gear, stress calculations and finally by the type of material.

Conclusion

A spur gear is a cylindrical toothed gear with teeth parallel to the shaft that is used to convey mechanical motion between shafts while also controlling speed, power, and torque.

The design, structure, and materials of a spur gear determine its performance. The fabrication of a spur gear, which includes the use of high quality materials and stringent and precise dimensional compliance that is used to establish a spur gear's function, is an important component of its creation.

Spur gears are manufactured using a variety of technologies, including forging, blank machining, cutting, casting, powder metallurgy, and computer numeric controlled manufacturing, to mention a few.

FAQs on Spur Gears

1. What is a spur gear and why is it called that?

A spur gear is the simplest type of cylindrical gear, characterized by teeth that are straight and parallel to the gear's axis of rotation. It is called a 'spur' gear because the teeth project radially outwards from the gear's cylindrical body, resembling spurs. They are designed to transmit power and motion between parallel shafts.

2. What are the main advantages and disadvantages of using spur gears?

Spur gears offer several key benefits but also have some notable drawbacks.

Advantages:

- High Efficiency: They have a high power transmission efficiency, often between 95-99%, due to low rolling friction.

- Simple Design: Their simple construction makes them easy to design, manufacture, and maintain, leading to cost-effectiveness.

- Constant Velocity Ratio: They provide a reliable and constant speed ratio between the driving and driven shafts.

- No Axial Thrust: Unlike helical gears, spur gears do not generate axial thrust, which simplifies bearing design and reduces load on the support structure.

Disadvantages:

- Noisy Operation: The sudden engagement of teeth can create significant noise and vibration, especially at high speeds.

- Limited to Parallel Shafts: They can only be used to transmit power between shafts that are parallel to each other.

- High Stress on Teeth: The full-line contact during engagement can lead to high impact stress on the gear teeth.

3. Where are spur gears commonly used in everyday applications?

Due to their simplicity and reliability, spur gears are found in a wide variety of mechanical devices. Common examples include home appliances like washing machines, blenders, and clothes dryers. They are also essential in industrial machinery such as conveyors, power tools, pumps, and in various automotive transmission systems for adjusting torque and speed.

4. What materials are typically used to make spur gears?

The choice of material for a spur gear depends on its application, load, and required durability. Common materials include:

- Steel and Steel Alloys: Used for high-strength and high-load applications due to their excellent durability and wear resistance.

- Cast Iron: Offers good wear characteristics and is easily machinable, making it a cost-effective choice for many industrial gears.

- Aluminium Alloys: Chosen when light weight is a primary concern, though they have lower strength than steel.

- Plastics (like Polyacetal/POM): Ideal for low-torque, low-noise applications, such as in office equipment or toys, where corrosion resistance and self-lubrication are beneficial.

5. How do spur gears fundamentally differ from helical gears?

While both transmit power between parallel shafts, spur and helical gears differ significantly in their design and performance. The primary difference is the orientation of the teeth. Spur gear teeth are straight and parallel to the shaft's axis, causing them to engage suddenly along the entire tooth face. In contrast, helical gear teeth are cut at an angle, allowing for a more gradual and smoother engagement. This makes helical gears quieter and better suited for high-speed applications, but they produce an axial thrust that spur gears do not.

6. Why are spur gears often noisy, especially at high speeds?

The noise from spur gears originates from the way their teeth engage and disengage. Because the teeth are straight, they make instantaneous line contact across their entire width as they mesh. This abrupt contact creates a sudden impact, which generates vibrations that we perceive as noise. As the rotational speed increases, these impacts occur more frequently and with greater force, leading to a significant increase in operational noise. This is a key reason why smoother-engaging helical gears are preferred for high-velocity systems.

7. What are some essential terms to understand when working with spur gears?

Understanding the following terms is crucial for designing and analysing spur gear systems:

- Pitch Circle: The imaginary circle on a gear that rolls without slipping on the pitch circle of a mating gear.

- Module (m): A fundamental unit that defines the size of the gear teeth. It is the ratio of the pitch circle diameter to the number of teeth. Gears that mesh must have the same module.

- Pressure Angle: The angle between the line of action (the line along which force is transmitted) and the common tangent to the pitch circles. Common values are 20° and 14.5°.

- Addendum and Dedendum: The addendum is the radial height of a tooth above the pitch circle, while the dedendum is the radial depth of a tooth below the pitch circle.

8. What are the common manufacturing processes for spur gears?

Spur gears can be manufactured through several processes, depending on the required precision, material, and production volume. Key methods include gear hobbing and gear shaping, which are generating processes that can create very accurate teeth. Other methods include milling, where a form cutter shapes one tooth space at a time, and for mass production, processes like stamping, forging, and cold drawing are used.